Keeping moisture in check constitutes a vital activity that guarantees the food-processing industry’s efficiency, safety, and quality. Unwanted humidity brings with it numerous problems, among which are product spoilage, microbial contamination, and glitches in the production processes. Therefore, modern solutions for dehumidification are prioritized, wherein they serve in making controlled environments that ensure the acceptance of food safety measures and enhance the best conditions for food products.

Understanding Humidity in Food Processing

The Role of Humidity in Food Quality

Humidity plays a crucial role in food quality during manufacturing and storage. Moisture present in the environment accelerates the growth of microbes, catalyzing the process of spoilage and contamination of food products. On the other hand, low humidity dries out products, thus destroying texture, taste, and overall food composition. The right balance during food manufacturing and distribution processes is, therefore, imperative to maintaining food integrity.

Key Impact: Condensation of water occurs in the presence of high humidity on all types of equipment and surfaces, creating ideal breeding grounds for bacteria and molds that threaten product quality, facility safety, and operational efficiency.

Food manufacturers have developed advanced dehumidification systems to maintain optimal moisture levels and prevent condensation, ensuring compliance with health and safety requirements. Controlling humidity becomes of utmost importance in food processing as it ensures customer satisfaction and prolongs shelf life.

Effects of High Humidity on Food Safety

High humidity contributes significantly to spoilage and pathogenic microbial growth. Moist conditions aid in the proliferation of bacteria, molds, and yeasts, particularly affecting temperature-sensitive foods such as:

- Dairy products – Susceptible to rapid bacterial growth

- Fresh fruits and vegetables – Prone to mold and decay

- Meat products – Risk of pathogenic contamination

Increased humidity also accelerates chemical reactions like oxidation, affecting fats and oils in food, leading to rancid and unpalatable tastes that make products unsafe to consume.

Optimal Humidity Levels for Food Production and Storage

| Food Category | Optimal Humidity Range | Purpose |

|---|---|---|

| Dry Foods (grains, powders) | 15-20% RH | Prevent clumping and mold growth |

| Fresh Produce | 85-95% RH | Retain moisture and freshness |

| Refrigerated Goods | 75-85% RH | Prevent moisture loss and condensation |

| Frozen Foods | Low absolute humidity | Prevent freezer burn and ice crystal formation |

Dehumidification Systems in the Food Industry

Types of Dehumidification Systems

The food industry utilizes various dehumidification systems, each designed for specific applications and requirements:

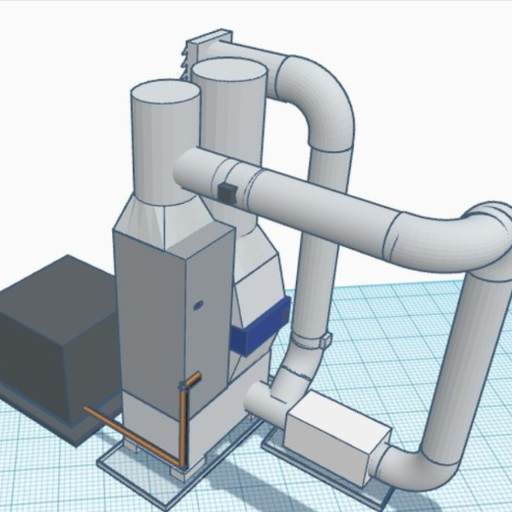

Desiccant Dehumidifiers

Apply hygroscopic materials such as silica gel or activated alumina, which adsorb moisture directly from the air. Can maintain dew points as low as -40°F, making them ideal for applications requiring tight moisture control.

Refrigerant-Based Dehumidifiers

Work by cooling air to the point where moisture condenses and can be removed as water. Suitable for moderate humidity control in fresh produce or dairy storage facilities.

Hybrid Systems

Combine desiccant and refrigerant technologies for efficient moisture extraction with precise temperature control. Increasingly used in multifunctional food processing plants.

Ventilation-Integrated Dehumidifiers

Combine dehumidification with ventilation functions, gaining popularity in controlled-environment agriculture and high-capacity warehousing.

Benefits of Using Desiccant Dehumidifiers

- Effective Moisture Removal: Achieve dew points so low that conventional refrigerant-based systems cannot cope, reaching humidity levels of 1-2% RH

- Energy Conservation: Advanced desiccant materials and heat recovery technologies reduce energy consumption by up to 30%

- Air Quality Enhancement: Remove airborne contaminants like bacteria and mold spores in addition to moisture

- Extended Equipment Life: Controlled humidity environments can enhance machinery life up to 20%, reducing maintenance costs

- Regulatory Compliance: Help meet environmental and safety standards across various industries

Energy-Efficient Dehumidification Solutions

Innovation Focus: Modern energy-efficient dehumidifiers can reduce energy consumption by up to 30% through advanced technologies like desiccant wheel systems, variable-speed compressors, and smart sensors that automatically adjust dehumidification levels based on real-time conditions.

Impact of Excess Moisture in Food Processing Plants

Consequences of Moisture on Product Quality

Excessive moisture directly influences product quality through physical, chemical, and microbiological changes:

- Physical Changes: Products lose crispness and structural integrity

- Chemical Changes: Accelerated oxidation reactions lead to off-flavors and nutrient degradation

- Microbiological Changes: Facilitate mold development and contamination

Risk of Food Contamination and Spoilage

The food industry faces significant challenges from contamination and spoilage due to microbial growth, chemical reactions, and physical deterioration. Key risk factors include:

- Bacterial Growth: Salmonella and E. coli thrive in warm, moist conditions

- Enzymatic Activity: Causes biochemical changes in proteins, fats, and carbohydrates

- Global Impact: Studies show nearly 14% of food produced worldwide is lost before reaching retail due to spoilage

How Moisture Affects Frozen Foods and Beverages

Moisture control is critical for frozen products, as poor control leads to:

- Freezer Burn: Sublimation from product surfaces causes dryness and flavor impairment

- Ice Crystal Formation: Temperature fluctuations destroy cell structure and reduce product integrity

- Ingredient Separation: In frozen beverages, improper moisture control causes texture issues

Implementing Proper Humidity Control Strategies

Best Practices for Humidity Management in Processing Facilities

Effective humidity control requires a systematic approach, including:

- System Selection: Choose appropriate dehumidifiers based on facility requirements

- Regular Calibration: Maintain accurate monitoring and response capabilities

- Real-time Monitoring: Implement sensors for immediate corrective action

- Staff Training: Ensure personnel understand humidity control procedures

- Maintenance Schedules: Establish rigorous maintenance programs

Monitoring Humidity Levels Effectively

Accurate humidity monitoring requires advanced instruments and methodologies:

- Digital Sensors: Calibrated hygrometers providing real-time data

- Wireless Integration: Seamless data communication to centralized systems

- Predictive Analytics: Software providing insights and warnings

- Compliance Standards: Adherence to ISO 17025 for quality benchmarks

Advancements in Dehumidification Technology

Smart Monitoring Capabilities in Dehumidifiers

Modern dehumidification technology incorporates smart monitoring for enhanced efficiency and control:

Real-time Environmental Monitoring

Embedded sensors monitor humidity, temperature, and air quality continuously, preventing over-drying or under-drying issues.

Remote Connectivity

Wi-Fi and Bluetooth connectivity enable mobile app control and smart home ecosystem integration.

Predictive Analytics

AI-based insights provide maintenance alerts and operational optimization recommendations.

Data-Driven Optimization

Machine learning algorithms analyze patterns to forecast and prevent humidity-related issues.

Innovations in Industrial Dehumidification Systems

Industrial systems have seen significant advancements in recent years:

- Advanced Desiccant Technology: Optimized moisture absorption with reduced energy consumption

- IoT and AI Integration: Environmental monitoring, predictive maintenance, and remote operation

- Eco-friendly Refrigerants: Use of R-32 and R-290 for environmental compliance

- Modular Designs: Scalable solutions for diverse industrial applications

Future Trends in Food Plant Dehumidification

The industry is evolving toward more sophisticated and sustainable solutions:

- IIoT Integration: Industrial Internet of Things for real-time monitoring and predictive maintenance

- Energy Efficiency: Rotary desiccant dehumidifiers with heat recovery systems

- Modular Systems: Customizable solutions for diverse plant requirements

- Antimicrobial Materials: Enhanced operational purity and health safety

Frequently Asked Questions (FAQ)

References

- Strategies to Reduce Moisture Condensation in Food Facilities

Comprehensive resource discussing food plants, dehumidification systems, and applications. - Strategies to Reduce Moisture Condensation in Food Facilities (PDF)

Detailed Oklahoma State University publication providing insight into surface treatments and dehumidification techniques. - Reducing Humidity in the Greenhouse

University of Massachusetts resource explaining humidity management methods relevant for food plant environments.