Understanding Portable Industrial Dehumidifiers

Portable industrial dehumidifiers are advanced machines that function to efficiently get rid of the excessive humidity from the atmosphere in industrial or commercial areas. They carry out the process by taking in the humid air, removing the moisture by either cooling or using a desiccant, and discharging dry air into the room again. These machines are appreciated a lot for their portability since they can be easily moved to different locations to solve the moisture problem. The most common uses are preventing condensation, protecting materials from being ruined by humidity, and keeping the conditions in storage or production facilities optimal. Their power and versatility make them already very desirable if the aim is to keep environmental conditions under control the right way.

What is a Portable Industrial Dehumidifier?

A portable industrial dehumidifier is a clutter-free device that is meant for removing excessive moisture from the air in industrial and commercial places. These machines are equipped with either sophisticated refrigeration or desiccant technology for efficient water vapor extraction, thus controlling moisture at the desired level and ensuring no growth of mold, rusting, or decay of the building. Portable industrial dehumidifiers, in contrast to fixed ones, are made with wheels or have handles allowing easy transfer to the area with the humidity problem. These devices are used in different places like warehouses, factories, and sites of construction and restoration, where they create a controlled environment and similar conditions for the equipment, materials, and workers’ productivity. Their ruggedness and efficiency make them indispensable for keeping the exact atmospheric conditions in the highly demanding industrial environments.

How Portable Dehumidifiers Work in Industrial Settings

The industrial sector relies on portable dehumidifiers, which take moisture from the air with the help of a fan that pulls the air in from the surrounding area. The first step in the process is the intake fan. Thus, after going over Refrigerated coils or desiccants, the air is worked on according to the dehumidifier’s technology. When air is made to pass over the cold coils, the water vapor is turned into a liquid and is either stored in a tank or discharged through a continuous drain. On the other hand, the desiccant process uses hygroscopic materials that are able to draw moisture even in low-temperature conditions. Before being vented back into the area, the dehumidified air is first heated.

These appliances use very sensitive sensors to not only regulate but also improve humidity levels, thus assuring maximum operation and sales efficiency. A number of models have settings that can be programmed and can be operated remotely, which makes them very flexible for the ever-changing requirements of the industry. Due to their ability to function nonstop and withstand extreme environments, portable dehumidifiers have become a necessary evil in protecting metal parts from rust, preventing the growth of mold, and avoiding any interruptions caused by breakdowns in the industrial sectors of production, warehousing, and construction.

Benefits of Using Portable Industrial Dehumidifiers

Portable industrial dehumidifiers are powerful amenities for different industries due to the several benefits they offer. To begin with, these units not only prevent damage caused by moisture but also keep it at a comfortable humidity level, hence avoiding corrosion, mold, and material weakness. Besides, their mobility gives them the advantage of being usable in all kinds of different places, which is a plus for the industries that can include construction, storage, and manufacturing, where moisture levels might change a lot from one site to another. Besides, dehumidifiers decrease the operational efficiency by first protecting the equipment from moisture and then saving the time lost due to malfunctions. In addition, these devices are often provided with modern controls, energy-efficient systems, and easy maintenance, which are the factors that guarantee savings and smooth adaptation of the equipment to any industrial workflow over time.

Importance of Humidity Control in Industrial Environments

In industrial environments, humidity control is a needful aspect for preserving product quality, ensuring the safety of the workers, and the functionality of the equipment. High moisture levels, among other things, can trigger the development of mold, the corrosion of machines, and the deterioration of materials, while low humidity conditions might create static electricity or make the products brittle. Therefore, humidity regulation assures manufacturing processes with uniform output, less disruption, and longer periods of use for delicate equipment. However, controlling humidity efficiently is not only necessary for the above-mentioned industries but also for others such as food processing, pharmaceuticals, and electronics, where very specific environmental conditions are required. Meanwhile, good humidity regulation turns the factory into a stable and productive place.

Impact of High Humidity on Industrial Facilities

High humidity levels in industrial buildings can result in a substantial drop in operational performance and asset life. The metal parts of the machines exposed to the humid air may start to rust, while the buildings may suffer from various structural cracks because of the moisture in the air, causing a failure in the electrical systems as a result of moisture entering the electrical space. Moreover, high humidity levels promote the development of molds and mildews, which create health hazards for workers and degrade the quality of materials such as food or medicines that must be under controlled storage conditions.

Industries that depend on precision manufacturing, like electronics and semiconductors, have to cope with further risks since high humidity levels will not only affect the accuracy of the products but also make the defect rate during production higher. A humid environment will also make air-conditioning units less efficient, thus raising energy expenses and causing temperature regulation to be inconsistent.

The use of advanced dehumidification systems, which include desiccant and mechanical-based technologies as well as non-invasive are among the most important strategies to address these problems. These systems not only remove excess moisture but also keep the right environmental conditions for a variety of industrial processes to take place. Humidity monitoring, along with regular maintenance, also helps to keep the operations of the facilities uninterrupted and without any compromised quality.

Water Damage Prevention through Moisture Control

The prevention of water damage to a significant extent depends on the use of advanced moisture control measures. The first step involves providing adequate ventilation in humid areas, like basements, crawl spaces, and bathrooms. The airflow will help a lot in reducing the condensation and moisture. Next, the laying of moisture barriers or application of waterproof membranes will be a sure way of keeping water from getting into the building, especially in the basements and outside walls of the building. It is also possible to use dehumidifiers and smart humidity monitoring systems that provide exact control and make the necessary adjustments in real-time to keep the indoor moisture levels at the optimum point to prevent mold and decay.

To prevent water damage, regular inspections should be done to spot the leaks early, which can be indicated by discoloration, warping, or musty odors. It is important to repair plumbing issues, seal gaps, and maintain drainage systems like gutters and downspouts on time to prevent moisture from accumulating. When combined with the recent technologies, those preventive practices can ensure that the facility is safe from water damage for a long time while its structural and operational integrity is also maintained.

Understanding Relative Humidity and Its Effects

Relative Humidity (RH) is a term that describes the amount of moisture in the air as a percentage of the maximum amount of moisture that the air can contain at a specific temperature. A high RH level will not only allow but also speed up the growth of mold, mildew, and bacteria, which will, in time, deteriorate the quality of air and become health hazards. On the other hand, low RH causes very dry skin and respiratory problems, and results in the gradual breakdown of materials such as wood and electronic items due to shrinkage or the accumulation of static electricity. The ideal RH level of 30-50% is a must for human comfort, and at the same time, it is a great contribution to the preservation of infrastructure. The use of cutting-edge monitoring systems along with dehumidification or humidification technologies can help manage the RH in a very effective way, thus making it possible to have an indoor environment that is always in balance and ready to change with the seasons.

Choosing the Right Portable Industrial Dehumidifier

The following critical factors should be taken into account when selecting a portable industrial dehumidifier:

- Capacity: Determine the size of the area as well as the usually wanted moisture removal rate (expressed in pints or liters per day). Choose a model that is fitted for the exact square footage of the place.

- Durability: Go for a heavy-duty design that comes with premium materials that can bear industrial conditions.

- Portability: Make sure that the unit is equipped with wheels or handles so that it can be effortlessly moved from one location to another.

- Energy Efficiency: Go for a unit that has high energy efficiency to cut down on the cost of operations in the long run.

- Additional Features: Look for features like variable humidistat controls, automatic defrost, and continuous drainage options that are facilitations for the user and also for the performance of the unit.

Considering these factors will enable you to make a better choice of a dehumidifier that not only fulfills your operational needs but also stays within your budget.

Factors to Consider When Selecting a Dehumidifier

When it comes to choosing a dehumidifier, it is very important to pay attention only to a few main things so that the appliance will have a good performance and will last longer. First of all, the capacity should be considered, which is stated in pints per day, as this tells how much moisture the dehumidifier can take out, and it should be determined according to the room size and its humidity. Energy efficiency is the next thing that is of utmost importance; Energy Star-certified models will require less electricity while delivering high performance. Then, think about the draining methods, which could be built-in pumps or continuous drain connections that would make maintenance very easy for you. For flexibility, the device should have humidistat controls that are adjustable and thus allow accurate humidity regulation, and look for features such as automatic shut-off to stop overflows. Finally, think over the device’s mobility and noise, especially if it is going to be used in a living room. Putting these aspects in order will guarantee you a dehumidifier that will cost less, will be easy to operate, and will be reliable for a long time.

Top Features of Commercial Dehumidifiers

| Feature | Description | Benefits |

|---|---|---|

| High Moisture Removal Capacity | Dehumidifiers for commercial use are made to remove huge amounts; thus, the majority of the types can get more than 100 pints of water every day. | Ideal for humid areas such as warehouses, basements, and industrial plants where humidity control is crucial for preservation and air purification. |

| Durability and Robust Construction | Made to last in difficult conditions with heavy-duty materials, reinforced components, and long warranty periods. | Designed for long periods of operation in hot and cold temperatures, providing reliability under hard circumstances. |

| Integrated Smart Controls | Features smart technology, including digital humidistat controls, remote monitoring, and programmable settings. | Enables accurate moisture control, quick changes, and remote operation for increased convenience and energy efficiency. |

| Drainage and Continuous Operation | Direct drain options with built-in pumps for continuous water discharge, minimizing manual water tank emptying. | Essential for round-the-clock dehumidification needs. |

| Portability and Versatility | Equipped with wheels, grips, and compact designs for mobility throughout various areas despite their large size. | Must-have feature for contractors, restoration work, or conditions requiring frequent unit relocation. |

In the process of choosing a commercial dehumidifier, one should think about the particular environmental requirements and those features that promote operational efficiency, safety, and ease of maintenance. The combination of the mentioned features will result in optimal performance, especially for your application.

Customer Reviews and Recommendations

The dependability and effectiveness of high-grade commercial dehumidifiers are always some of the best features that customers point out. The reviews often acknowledge that aspects as excellent control over humidity, energy saving, and low noise levels are the reasons behind that. Dehumidifiers made of resilient materials and equipped with diverse options, like easy-to-operate digital controls and adjustable settings, are strongly recommended for different applications.

The customer opinions collected from the leading online sources suggest that dehumidifiers with higher daily extraction rates (pints taken away), along with built-in automatic shutdown or freeze protection, offer the best performance in the long-term. Besides, customers pay more attention to the maintenance aspect and consider washable filters and easy drainage as the most important features. Giving strong after-sales support, prolonged warranties, and offering accurate documentation are the ways through which brands win buyers’ trust and satisfaction. These considerations should lead to your selection of a commercial dehumidifier that will work effectively and last long.

Applications of Portable Industrial Dehumidifiers

Portable industrial dehumidifiers have now become indispensable tools for most of the industries that need to control humidity levels and secure their premises. The main areas of application are as follows:

- Warehousing and Storage: Shielding goods against moisture, particularly in buildings that store food or items requiring special care.

- Construction Sites: Speeding up the process of drying concrete, paint, and plaster by controlling the growth of molds at the same time.

- Manufacturing Plants: Regulating humidity levels to the extent of ensuring the quality of raw materials and finished products.

- Flood Restoration: Draining water after incidents of flooding to avoid both decaying and the formation of microbes.

- Data Centers: Keeping the critical electronic equipment free from malfunction due to humidity.

It is obvious that these multipurpose appliances are the main factor in operating efficiency and the protection of precious assets in areas with a high level of humidity.

Moisture Control in Restoration Projects

Moisture control that is effective is basically a vital aspect of restoration projects, especially when flooding is involved. The entire process usually includes measuring the humidity, pumping the water out, drying things up, and keeping a watch on the situation to make sure no more damages happen, like the weakening of the structure, the growth of fungi, or the breakdown of the materials. A lot of different advanced methods and tools are available, among which are the heavy-duty industrial dehumidifiers, air movers, and moisture meters to cut down on the drying time while maintaining accuracy.

The essential stages consist of figuring out and not letting the leakage happen, making an atmosphere for the drying that is under control, and constantly testing the moisture levels for the industry to be compliant, such as those set up by IICRC (Institute of Inspection, Cleaning, and Restoration Certification). In the process of keeping the moisture levels in the best condition, the professionals doing the restorations guarantee the strength of the building and the prevention of extra complications like mold, which can come up as fast as in 24 to 48 hours, that is, the microorganisms growing and decaying of the materials. The team of experts collaborating with the state-of-the-art tools leads to successful results in restoration efforts.

Utilizing Dehumidifiers in Different Industrial Spaces

Dehumidifiers are essential devices for controlling humidity levels in various industrial environments like manufacturing plants, storage facilities, and computer rooms. They mainly serve to control and eliminate the problems that highly humid areas usually cause, such as condensation, rust, mold, and equipment damage.

Manufacturing Plants: In the pharmaceutical, electronic, and food processing industries, where humidity control is thought to be very critical, dehumidifiers will still maintain the required humidity level. This will not only help in keeping the quality of the product but also in reducing waste and creating a conducive environment for production.

Warehouses: Warehouses frequently accommodate goods that are moisture-sensitive, for instance, papers, textiles, or metal parts. The use of large dehumidifiers in warehouses will prevent rust, mildew, and the deterioration of materials, therefore prolonging the life of products and protecting the inventory.

Data Centers: For data centers and server rooms, nothing comes as essential than accurate environmental control. High humidity could bring about the precipitation of water on the hardware, and as a result, the hardware would become inoperative or damaged permanently. On the other hand, the dehumidifiers will always be there to support the maintenance of the ideal operating conditions and hence the reliability and efficiency of the critical IT equipment.

In conclusion, the use of dehumidifiers that are designed according to the different requirements of these environments will not only reduce risk but also improve the efficiency of operations and make the industry productive over the long haul.

Residential vs. Commercial Dehumidifier Needs

| Aspect | Residential Dehumidifiers | Commercial Dehumidifiers |

|---|---|---|

| Purpose | Designed for houses and smaller rooms, targeted towards comfort and prevention of mold, mildew, and allergens | Designed for big, demanding environments such as warehouses, offices, and manufacturing plants |

| Capacity | 20 to 70 pints per day, depending on area size and humidity level | More than 100 pints of water per day for heavy-duty operation |

| Features | Prioritize energy conservation, quiet operation, portable designs, and simple controls | Equipped with durable parts, continuous drainage systems, advanced humidity controls, air filtration, and temperature control |

| Design Focus | Convenience and user-friendliness | Durability and performance for industrial applications |

Selecting the right unit between the residential and commercial dehumidifiers requires taking into account the aforementioned factors, namely space size, humidity level, and specific environmental conditions, so as to guarantee top performance and protection.

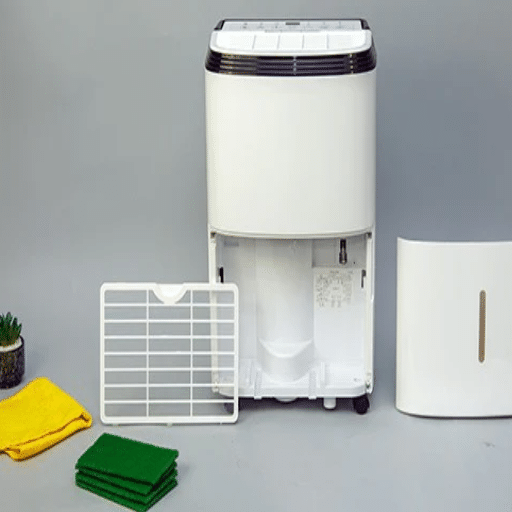

Maintenance and Care for Portable Dehumidifiers

The proper upkeep of a portable dehumidifier is crucial to its efficiency and lifespan. Here are the key steps:

- Regularly Clean the Filter – Inspect and clean the air filter every few weeks or as the manufacturer suggests to avoid dust build-up and to keep good airflow.

- Water Tank Emptying and Cleaning – It is advisable to frequently empty the water tank to prevent overflow and to clean it on a regular basis to stop mold or bacteria from growing.

- Inspecting and Cleaning Coils – If the coils can be reached, clean the evaporator and condenser coils to get rid of dust and debris that might lower their efficiency.

- Check and Replace Parts – Check seals, hoses, and other parts periodically for wear or damage and replace them if necessary to maintain the best performance.

- Proper Storage When Not in Use – Before putting the unit away, drain the tank, give it a thorough cleaning, and store it in a dry, cool place to avoid damage and be ready for the next use.

A portable dehumidifier will, thus, be able to run well and also have a longer operating lifespan if these simple care routines are followed. Always check the manufacturer’s manual for the specific recommendations.

Regular Maintenance Tips for Longevity

A structured maintenance routine is crucial for the portable dehumidifier to run efficiently and to last longer. Here are compact yet detailed suggestions based on the practices that are mostly recommended:

- Clean or Change the Air Filter Frequently – In almost all dehumidifiers, there is an air filter that traps dust as well as allergens. Make monthly checks on the filter, and if it is washable, clean it with mild detergent and warm water. Follow the manufacturer’s instructions for replacing non-washable filters and prevent blocking of the airflow.

- Look at and clean the Coils – The combination of dust and dirt can significantly decrease the effectiveness of the unit, which is the dehumidifier’s coils. First, unplug the unit and then very gently clean the coils with the help of a soft brush or vacuum to get rid of the dirt, thus keeping the moisture extraction effective and preventing overheating.

- Discharge and Clean the Water Reservoir – If you want to keep mold and bacteria from progressing, you should frequently empty the water tank. Do a proper rinse at least once a week, using a mild cleaning agent if needed, and let the tank completely dry before connecting it again.

- Provide Ventilation – To prevent overheating and to allow the unit to work at its best, place the dehumidifier in a spot with good airflow around it with a clearance of at least 12 inches on all sides.

- Check the Humidity Sensor – Monitor the hygrometer or humidity sensor every so often to make sure that the readings are correct. It might be necessary to carry out the calibration if the system is giving wrong data, which is usually included in the manufacturer’s manual.

- Inspect for Leaks or Malfunctions – Check hoses (for continuous drainage models) and connections on a regular basis for leaks. If there are any strange noises or problems with the operations, get help from a professional or the manufacturer quickly.

With the support of these regular maintenance practices, the dehumidifier is going to be effective for a period of time, leading to a decrease in operating costs and needing repair only once in a while.

Common Issues and Troubleshooting

In case of dehumidifier issues, I typically follow a systematic approach to pinpoint problems. Checking the power cord connection and the circuit breaker, I start by verifying the working state of the dehumidifier if it does not turn on. If the efficiency is low, I first clean or replace the air filter and then check that there is no obstruction around the airflow vents. If the dehumidifier is not gathering water, I look at the humidity settings and also check if the room temperature is within the unit’s operational range. If there are constant leaks, I check the hose connections and also make sure that the water tank is placed properly. By dealing with these problems in a structured manner, I am usually able to take care of most issues quickly.

Importance of Humidistat in Maintaining Optimal Performance

The humidistat is actually one of the most important components in a dehumidifier, and its main task is to keep the humidity level stable by checking and controlling the desired settings. Its operation is based on revealing the percentage of humidity in the air and accordingly notifying the machine to turn on or off. This practice guarantees the best possible performance, avoidance of over-drying, and energy saving. Humidistat calibration is quite delicate; its low setting might result in too dry air, which could be harmful for both people and furniture, while a too high setting might allow the air to be so moist that it will lead to mold and structural problems. The benefits of monitoring and calibrating the humidistat include dehumidifier efficiency and longevity since the unit is assured to be working under its designated specifications.

Reference Sources

Energy Star – Dehumidifiers: Provides detailed information on portable and whole-home dehumidifiers, including their energy efficiency and applications. Visit the source

Federal Register – Energy Conservation Standards for Dehumidifiers: Offers insights into energy conservation standards and industry benchmarks for portable dehumidifiers. Visit the source

Acker & Associates – Industrial Dehumidification: Discusses energy usage, calculations, and operating costs for industrial dehumidification systems. Visit the source

Frequently Asked Questions (FAQs)

Do you think a portable industrial dehumidifier could be beneficial for controlling humidity in a room that was previously water-damaged and restored?

Certainly. A dehumidifier is a portable industrial apparatus that is widely used in water damage restoration by removing the moisture that is excess in the air as well as the affected surfaces. Despite the fact that these units are made for commercial and industrial environments, they can still effectively be applied in homes or garages that have experienced flooding on a smaller scale. They are also the backbone of the moisture removal process as they complement other equipment like air movers and steel-framed containment to speed up the drying, lowering the risk of mold growth, and preserving the installed machinery and building materials from the adverse effects of high humidity.

What kind of features should a buyer expect to find in a portable industrial dehumidifier that is suited for humidity control?

When buying, consider the portable units that can accommodate the area you want the dehumidifier to be, with a good capacity, have humidity control with an adjustable range, strong construction (for example, steel cabinets are the norm for industrial models), and have castor wheels and handles, which make it easy to move. Factor in electric power requirements, utility costs, and whether the model is rated for commercial and industrial use. In the case where you have water damage, make sure it has the option of support for continuous drainage or a pump if it doesn’t already have one.

Are portable industrial dehumidifiers still considered an expensive investment in terms of their worth for commercial and industrial operations?

In most situations, portable industrial dehumidifiers are indeed an expensive investment that is still very much worth it if you are looking for a reliable moisture control solution in your equipment rooms, manufacturing areas, or in the post-flood stage of the water damage restoration process. They not only shield the delicate machines and products but also improve the quality of the product by reducing corrosion; thus, they are always a good investment. In case the owner is not quite sure if he/she should buy or rent, then the factors to be considered are the frequency of use, transport requirements, and maintenance; renting is likely to be more favorable for isolated cases in the past two years, while the purchase fits ongoing humidity control.

In what way do portable units and installed systems compare in terms of humidity control in an interior space?

Portable units offer flexibility, quick deployment, and lower upfront cost compared with permanently installed dehumidification systems. Installed systems may be more efficient for whole-building climate control, but portable industrial dehumidifiers excel in targeted applications like a single contaminated room, garage, or around specific machinery. Portables are also accessible for emergency water damage restoration and can be moved where needed.

Is transporting a portable industrial dehumidifier between jobs still going to give me the same great performance as if I were using it at one location?

Yes—portable commercial dehumidifiers are designed for transport and repeated deployment. Look for units with durable steel construction, protected controls, and sturdy casters. Follow manufacturer guidelines for handling and inspect for damage before use. Proper transport makes these units ideal for contractors who perform water damage restoration across multiple job sites.

How to take care of a portable industrial dehumidifier to keep it working beyond the time period of the last two years?

Preventive maintenance is done through efficient performance of the dehumidifier, including the filter replacement or cleaning, monitoring the accumulation of dust in coils, ensuring the condensate drainage or pump function is working, and checking electrical connections. For models used in areas of heavy equipment or in commercial and industrial environments, schedule periodic professional servicing. Proper treatment will help retain the value of the unit, whether you purchased it or it was rented.

In what instance is it safe to operate an industrial portable dehumidifier in, say, a garage or close to a sensitive machine?

Yes, but only under the right conditions. Make sure ventilation is sufficient, and a stable placement is done to avoid unit tipping. Electrical connections must remain dry, and the manufacturer’s instructions on acceptable temperatures and distance from the machine must be adhered to. Moreover, industrial units are equipped with features to protect internal parts from dust, thereby making them suitable for commercial and industrial workspaces; however, keeping an eye on humidity and condensation is important to prevent new moisture problems around sensitive equipment due to a lack of monitoring.