Industrial dehumidifiers play a significant role in various fields, such as manufacturing, warehousing, food storage, and healthcare. The desire to use them to control humidity has often sparked debates on the safety of such devices in certain spaces. But are industrial dehumidifiers safe, and how do they function in order to guarantee that performance remains uncompromised? This paper aims to examine the mechanism, uses, and concerns regarding the use of industrial dehumidifiers. If you happen to be a facilities manager, an entrepreneur, or even a person who may be interested in the concept, you will know the advantages, the risks involved, and how to operate them safely. Let us discuss in detail these useful instruments, why and how they are used to keep a particular area protected from unwanted elements.

What is an Industrial Dehumidifier?

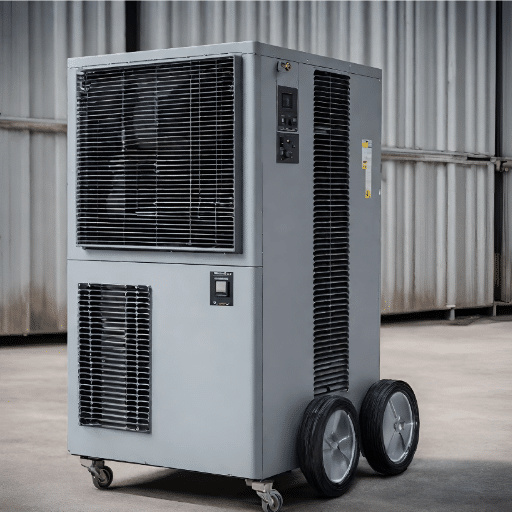

A commercial-grade humidifier is a special machine intended for drying up large areas like storage rooms, buildings with excessive moisture, or manufacturing facilities. It is useful in minimizing the risk of equipment damage as well as mold formation or decomposition of stored food and similar products. Since they are meant to dry up very large volumes of liquid, however, these units have also become an integral part of many industrial and storage settings to achieve the best possible climate control.

Definition and Purpose

High-capacity ambient air dehumidification, engineering units, with engineered control room conditions for their deployment, are designed to manage and control humidity levels found in large industrial spaces. As a secondary function, its condensation controls also regulate very low humidity levels in order to ensure protection of equipment, storage of perishables, or non-perishable products in atmospheres where humidity or temperature is critical. At any rate or rate, these devices work by dehydration of air through cooling or adsorption and evidently, assist in reducing the drying time, maintenance of equipment and other assets, as well as improving the manufacturing, warehousing, and logistic activities.

How Industrial Dehumidifiers Work

The properties of an industrial dehumidifier: it is furnished with equipment to be useful in removing unwanted moisture in the air. Those devices use a fan to draw the humid air, which is subsequently directed over the cooling coil or through a desiccant medium, depending on the type of dehumidifier used. The refrigerant type of dehumidifiers cools down the air to the point where condensation of water starts (also known as the dew point) collection or disposal of which is ensured. On the other hand, the desiccant dehumidifiers contain moisture-absorbing materials to pull out the moisture from the air, which works very well in the case of cold or dry air. After the dehumidification of the air, it is heated and returned to the space. This systematic method of operation allows proper humidity regulation, which is important in ensuring equipment condition, quality of goods, and the efficiency of processes in factories and other industrial organizations.

Different Types of Industrial Dehumidifiers

There are many different types of industrial dehumidifiers that workers employ in managing appropriate humidity levels within a building structure. The principal categories include refrigerant-based dehumidifiers, desiccant dehumidifiers, and hybrid systems.

Refrigerant-Based Dehumidifiers

Such devices tend to operate by lowering the temperature of the air to such an extent that moisture begins to condense out of it through their exhaustive cooling mechanism. These dehumidifiers have been commonly employed in the food processing and even in the storage industries due to their operational features, which work best when dealing with environments that have high humidity but are moderately warm. Even today, they are extremely useful for the moisture that they have, as much as they are energy-conserving and simple in their functioning.

Are industrial dehumidifiers safe in enabling the regulation of water vapor in the air? Such devices do meet nearly all contemporary needs, but their real significance lies in drying place which does not have sources of hygienic facilities.

Those types of humidifiers work by using absorbent materials like silica gel that trap the water from the surrounding air. They perform very efficiently in low temperature and low humidity conditions, hence their best fit in some industrial sectors like pharmaceuticals and electronics. Desiccant dehumidifying systems are distinguished by maximized capacity to reduce humidity levels on a sustained basis and by their indomitable construction.

Systems of Hybrid Dewatering

Utilizing both processes, Cooling and Dehumidifying Processing, hybrid driers help increase the efficiency of the working environment, irrespective of the prevailing conditions. Such units find extensive usage in sectors where deep conditioning is essential for product quality, for instance, those involving chemical processes and even space equipment manufacturing concerns.

Whether or not to use a particular dehumidifier would, however, be based on considerations such as the range of working temperatures achievable, the expected moisture, and the structure of the process that shall be made. Correct implementation and vigilance care guarantee effective moisture management and also extended durability of the machinery.

How Do Dehumidifiers Work?

Dehumidifiers are designed to remove excess moisture in the air so that the humidity is controlled and maintained within certain desired limits. When switched on, such machines work on the principle of drawing in the air through a fan and passing it over coiled tubes containing a refrigerant, which cools the tubes, and hence the moisture in the air condenses in water droplets. This water is collected either by draining it or by placing it in an available container within the dehumidifier, and the warm, dry air is returned to the room. Reduction to proper levels of air, water vapor, andelements such as condensation, mold formation, and materials degradation is achieved through this principle.

Principles of Dehumidification

Dehumidification manipulates humidity to levels within a controlled range by applying techniques of air drying or moisture reduction. Two types of dehumidifiers are generally in use: those based on refrigeration and those based on desiccants. Refrigeration types work by cooling the air to such an extent that it is below its dew point, and as a result, water vapor becomes liquid, which is collected or discharged. The latter desiccant dehumidifiers utilize chemicals such as silica gel to dry up moisture-laden air without cooling it. These techniques are employed in order to maintain the humidity of the indoor space at a comfortable range, say, 30-50%, which prevents mold growth, dampness of buildings, and promotes the cleanliness of the air. More sophisticated devices may also possess features such as humidistats that can turn them on and off according to the conditions, economy modes, or even sometimes antibacterial filters for preventive purposes.

Components of Industrial Dehumidifiers

Is it dangerous to use industrial dehumidifiers the way they were designed? The answer is simple: part of the design of the equipment is numerous components that cooperate in order to make sure the moisture is controlled at an acceptable level. The main parts are:

- Compressor – At the center of the refrigeration process is the compressor, where refrigerant gas is compressed so that heat is dissipated and the extraction of water from air is accomplished by condensation.

- Evaporator Coils – These evaporator coils are used to cool down and dry out the warm, humid incoming air below the dew point of the air. This converts the water vapor in the air to water for collection and eventual drainage.

- Condenser Coils – In addition, the condensation of steam allows the heat of removal to be reused; the fans that expel the churned and conditioned air are whirled through a condenser so that the trailing edge of the machine does not emit cool air.

- Fan or Blower as Dirt or Vegetation or water and Litter will not affect the Function of the Ventillator – Large fans, powered by electricity, intake moist air and spin the air around parts that have undergone treatment, aiding in making the moisture removal in the OBJECT more efficient.

- Water Drainage System – In moisture capture devices, the captured moisture is either retained in a tank or drained off through a drain tube, based on the configuration of the machine. More sophisticated systems integrate pumps, so that water may be removed automatically.

- Filter System – Provides air filters to retain dust, allergens, and any other suspended debris that may be present in the air for preservation of air quality, as well as protecting the internal mechanism from damage. Some models also provide HEPA and/or antimicrobial filters for cleanliness purposes.

- Control Panel and Humidistats – The humidistats help in regulating the present humidity level of the environment in question through their linear control console. Many models also provide technology advancement of automatic configurations and programming for different applications.

These component modules have been combined and engineered with sufficient care that lasing in extreme-working conditions for industrial dehumidifiers is a possibility. There are such conditions that are associated with industrial applications, storage of goods in warehouses, and cold storages among others.

Efficiency Ratings and Temperature Range

When assessing industrial dehumidifiers, they are industrial dehumidifiers safe considered on their Energy Factor (EF), which is the performance of water extraction for each kilowatt consumed (L/kWh). In most cases, high-efficiency units would have an EF of at least 2.5 L/kWh or higher, meaning lower energy consumption in operation. Such extremes are required since these appliances are built to work effectively within certain temperature limits. The majority of the conventional units work perfectly well in the temperature range between 41°F and 95°F (5°C and 35°C), while special low-temperature units have a defrost system to allow efficient working as low as 33°F or 0.5°C. Therefore, to avoid wastages and to facilitate stable functional levels even under stressful industrial environments, one should take into account the efficiency values and the normal working temperature range when choosing any model.

Benefits of Using Industrial Dehumidifiers

- Moisture Management: Industrial dehumidifiers are highly effective in removing excess humidity. Therefore, they help control condensation and eliminate risks of such fungal phenomena as mold and mildew or corrosion.

- Protection of Objects: In turn, controlled levels of humidity for these systems also help protect susceptible materials and products against moisture damage.

- Increased life of the Equipment: Very low percentage of moisture in industrial settings reduces the chances of the machinery and tools rusting and any other form of moisture wear and tear.

- Healthy Air: Nitrogen and argon use will crowd out humidity levels in areas where they are not conducive to healthy work, as well as suppress the ecoalternative, which is to let pathogenic organisms grow in the air.

- Energy Saving: Modern industrial dehumidifiers are designed in such a way that they provide a continuous operation using the least energy, making it cost-effective in the long run.

Such considerations make pursuant to the expenses attendant to the work in question, are industrial dehumidifiers safe?

Improving Air Quality

Enhancing the quality of air across the industrial spectrum is made possible by understanding and resolving the presence of airborne sources of pollutants. Installing an improved air system to capture aerodynamic solids and gases, air circulation is also encouraged by the installation of ventilation systems, and air dehumidifiers are used to control the humidity levels, which prevents the growth of microorganisms. Periodic maintenance of systems such as this is important to keep them at their most efficient state and reduce the resuspension of pollutants. The changes that need to be done, if any, air quality measuring devices are used help keep a check within the bounds of health, occupational, and environmental limits. Furthermore, improving air quality within factories and other industrial buildings can also benefit from processes together with equipment characterized by lower operational emissions.

Preventing Mold and Mildew

Effective regulation of moisture and humidity is an essential requirement for managing the growth of mold and mildew fungi, which grow in moist areas. This includes ensuring that those regions of a building that contain moisture, including toilets, kitchens, and basements, are well ventilated. Good air conditioning practice, which incorporates dehumidification, enables one to reduce the indoor relative humidity to less than 50% helps in restraining the growth of molds within the structure. Ongoing roof, wall, plumbing, and structure leaks need to be inspected and fixed as soon as possible, in order to stop supplying water for molds. The moisture present on the surfaces or materials that have just been wet should be cleaned and dried within two days at the very extreme. It is also possible to take measures such as using moisture-apart preventive measures for mold, such as use of deposition-resistant surfaces or paints.

Enhancing Equipment Lifespan

Strategies for equipment longevity require putting in place maintenance plans, using equipment properly, and investing in control measures. Scheduled maintenance and care, such as greasing and adjusting equipment or quite simply replacing the worn-out elements, lowers concerns of breakdowns and guarantees efficiency. Respecting the manufacturer’s instructions, such as the maximum permissible load or the temperature limits, prolongs the life and usefulness of the equipment. It is equally important to ensure that equipment is not kept in harsh environments and that covers are placed on the equipment for protection, and that such measures shall ensure against corrosion and degradation. Performance management systems that aim to measure and track different aspects of performance for the sake of anticipatory maintenance are also worth investing in. The combination of all these methods significantly increases the longevity of the equipment and minimizes the downtime.

Safety Considerations When Using Industrial Dehumidifiers

In doing so, are industrial dehumidifiers safe? Yes, they are. But it is important to remain aware of a number of considerations, including the ones discussed below. The first one would be ensuring that sufficient ventilation is provided to the space where an industrial dehumidifier is operating. This is to avoid any chances of heat build-up and air pollution. It is very important for the user to check that the wiring connecting the device is suitable and connected in an appropriate manner to the device, preventing any risk of electricity-related accidents. Ensure that the dehumidifier is emptied and cleaned regularly to prevent any problems in the function of the device caused by congestion of the congestion. It is important for the user to use the dehumidifier in a safe manner, as device-specific instructions are always available, and gloves when using parts for which cleaning of filters is necessary. Finally, do not use the device in flammable liquid environments and gas-containing atmospheres for purposes of avoiding cases of fire and explosion.

Electrical Safety and Drainage

For safety reasons, always plug the dehumidifier into a well-grounded electrical socket. Extension cords should be avoided due to the risk of heat accumulation and fire. Inspect the power plug and lead to make sure there is no wear and tear, and if there is, replace it in time to avoid electrocution or electrical shorting. Prior to any service maintenance or cleaning, make sure that the unit’s plug is removed from the wall socket.

If making a decision on how to get rid of the water, one may drain it manually by draining the container or installing an online system if the device is compatible. Properly connect a hose to the drainage hole, and orient it towards a suitable place such as a sink or a floor drain. Ensure that the area does not have debris or clogs that may lead to spillage or leaking. Be sure to install drainage correctly, according to the manufacturer’s guidelines, so that the system can run smoothly and in order to avoid any misuse.

Proper Installation and Maintenance

Getting the best possible performance out of a dehumidifier involves many factors, with installation and maintenance topping the list and rightfully so, as they both help to improve and extend the dehumidifier’s useful life. If it is about installation, it is necessary to install the dehumidifier in the middle of the area, which will ensure enough airflow and also at least a distance of 6 – 12 inches around it so that air inlets are not blocked by surfaces such as walls or furniture. In addition, the situation of such an enclosure should not be one in which temperature and moisture levels greatly fluctuate, but rather the same. In addition, make sure that the unit is level before plugging it in so that the water chamber does not shift, thereby optimizing the use of the unit.

Concerning upkeep, the air conditioner filter should be cleaned every 2-4 weeks for better air flow and energy use of the apparatus. The manufacturer’s guide should be consulted thoroughly for ways and when the task should be done. If there is a water tank in the unit, make it a routine to clean or empty it with a little soap from time to time to avoid mold and bacteria. In the case of units with continuous drainage, inspect the hose attached for clogs or twists every now and then.

What is a virgin mic but just an industrial dehumidifier, that is to say do frost or dirt, and especially in low temperature zones? This is because low temperatures cause frost, which in turn interferes with the function of the machine. It will, however, be tested if this is possible since most of the systems automatically switch to defrosting when the outdoor temperature causes the coils to freeze. It is advisable to consult the user manual for verification of these performance specifications. The filters and coils should be checked for stagnant air as well as any foreign particles that may have settled before any problem arises – this will help in lowering the cost of repair, prolonging the service life of the unit, and preserving adequate moisture retention. During any maintenance task, do not forget to switch off the device and remove the plug from the socket as a primary and foremost precaution.

Manufacturer Guidelines and Compliance

While the use of dehumidifiers, the equipment’s performance, safety, and compliance can be achieved when the manufacturer’s manual is followed. Equipment handling and operation instructions commonly include the following:

Situating/Affixing

It is accepted practice to place a unit on a flat surface and in a well-ventilated place. The recommended distance to the wall or furniture by the manufacturer shall always be observed. Check electrical wiring meets the installation requirements, as well as the appliance’s voltage rated how it works.

Suggested Timetable of Servicing

Air filters frequently get dirty and must be cleaned or changed since the air stoppage weakens the effectiveness. Water storage devices and drainage pipes should also be checked and cleaned, as mold may develop. Some provide general forms of water replacement and usage of the equipment every calendar month.

Efficiency, Energy, and Approval

Make sure the unit conforms to these benchmarks, including certification of energy conservation, such as ENERGY STAR. Check if it conforms to local standards of efficiency and sustainability in the user guide.

Safety signals

Use of earthed or fused power plugs and compatible extensions where necessary only. Do not block the air vents or subject the appliance to very high or very low temperatures, as this will degrade the appliance and may even make it dangerous to use or maintain. Follow all safety instructions as established therein.

By evaluating the instructions issued by the manufacturer and related third-party documents, a user is assured that the machine will work effectively under safe conditions and within the limitations of applicable regulations. If more information is needed, one may use appropriate sources, such as professional service providers or websites that sell such products.

Choosing the Right Dehumidification Solutions

All factors – area size, moisture levels, and the use of equipment- must be taken into account when choosing a suitable dehumidification approach. In households, one needs sufficient moisture around portable units that will cordially rehabilitate apt spaces. In larger areas, for instance, the role of moisture control will mean bigger capacity dehumidifiers or using the desiccant systems. In this regard, ensure that the ppd of the units meets the requirements of the habitat. Consider also prioritizing power-efficient models and those with modifiable controls to enhance the operation. Make sure the equipment complies with any relevant health and safety legislation as well as performance standards that will be in force for its use.

Factors to Consider When Selecting a Dehumidifier

To help you choose the most appropriate dehumidifier and ensure its effective operation, consider several important criteria:

Capacity and the Area to Be Cooled

Examine the capacity of the device, usually measured in pints per 24 hours, in connection with the actual space and humidity where the unit will be placed. For small areas, a capacity of 60-80 dl may be quite sufficient; for bigger rooms or areas with high humidity, products providing over 120 dl may be necessary. Check with the manufacturer’s recommended covered area for reference purposes.

How to Select a Dehumidifier

It can be confusing to decide whether to choose a refrigerant (or compressor) dehumidifier that is recommended for moderate to high temperatures or a desiccant dehumidifier that is more efficient at low temperatures. The decision on which type to use is based on the environment and the activity being carried out.

Resource Conservation

There are Energy Star-approved units, which are highly energy efficient as less power is used for their activity with the same humidity-controlled levels. This also minimizes the cost of operating the equipment and ensures energy-saving practices for the betterment of the environment.

Other Features

Some significant characteristics of any given system comprise a moisture control adjustment mechanism, programmed shut-off, ability to run continuously, and no drainage, and incorporation of a hygrometer as elementary features. Amongst the many other features embedded in certain models, a noteworthy one is the fact that the design allows for the incorporation of purifying systems to assist overall air purification.

Sound Force / Decibels and Volume

Decibel readings of the loudness of a product, especially for home and office dehumidifiers, need to be checked. Also, confirming the size of the unit is crucial so that it easily fits in the dehumidification area.

Upkeep

Maintenance of the Dehumidifier also plays a role. Discharge capacities, regularity of cleaning, and/or change of the latter and/or its details are variable factors pertaining to maintenance of the respective models. There are models with automatic cleaning and/or washable/cleaning-free filters, meaning less maintenance is involved.

Government Health and Safety Obligations

It is crucial to confirm whether the unit meets basic occupational drug safety standards that are required of it. Safety and performance standards may have been met if the product is labeled with the UL, ETL, or CE marks.

When these elements are well resolved, it is possible to choose a device based on your needs, availing its functionality and profitability for a longer period of time.

Comparing Commercial vs. Industrial Dehumidifiers

When asked to compare, what are two major distinctions between a commercial dehumidifier and an industrial one? The common answer is the capacity and the strength of the materials deployed, and where those materials are deployed. Most commercial dehumidifiers can sustain continuous use in moderate spaces such as offices and stores, removing moisture in these areas. In contrast, industrial-grade dehumidifiers provide efficient moisture removal in heavy-use areas such as warehouses or production facilities, where there is high humidity and aggressive use. These are core characteristics of any dehumidifier that has higher than average extraction volumes, high-strength materials, and usually more features to accommodate the harsher operating environment. Using it or a device similar to it will depend on the situation and the process involved.

Top Dehumidifier Manufacturers and Their Offerings

When sorting out which brand to pick, it might be a good idea to see what underrated manufacturers and their range of good-quality dehumidifiers are currently in the market, and meet the requirements. The top bands for this segment are:

Frigidaire

When it comes to domestic dehumidifiers, Fridgidaire is one of the manufacturers well known for producing premium quality, energy-friendly, and easy-to-use units. Users will appreciate the fact that many of the appliances offer features such as the ease of emptying a full tank and draining the water, as well as supporting customized humidity levels. A large number of the models come with Energy Star ratings, which means that the power consumed is reduced, but the moisture control remains efficient.

Aprilaire

Aprilaire is best known for its whole-home dehumidifiers designed to handle large capacities for both domestic and commercial markets. They are built to fit readily into HVAC systems and enhance the efficiency of the entire humidity control system in large areas. They are well-built and come with reasonable warranties for long-term use of Aprilaire products.

Honeywell

When it comes to dehumidifiers, Honeywell has an extensive line that includes the consumer as well as the commercial segment. Their home portable dehumidifiers are industrial dehumidifiers safe for ease of transport, as well as digital humidistats and even some safety features like auto shut-off. For high-capacity purposes, Honeywell manufactures heavy-duty dehumidifiers that can withstand very harsh environments, as well as extraction capacity is quite high.

Conclusion: These brands offer a range of functional solutions for different requirements of moisture control. Some brands are better suited to particular applications than others. Before selecting the brand and model, you should know under what conditions you want to operate it and for what purpose. Or in short, this is compatible with your use case. Check the product specification and reviews of previous users before making any judgment and before buying the sample.

Reference Sources

Water Intrusion SOP – UMass Boston

A standard operating procedure document addressing safety considerations for using dehumidifiers in water intrusion scenarios.

Indoor Air Quality – East Carolina University

Explores the use of dehumidifiers as part of industrial hygiene practices to ensure safe air quality.

Frequently Asked Questions (FAQs)

Are commercial dehumidifier units safe for large spaces like storage facilities?

Commercial dehumidifiers, in general, do not harm the environment, do not pollute, and don’t emit any ODS, and are capable of handling large spaces such as warehouses as long as they are set up and maintained properly. The main purpose of these systems is to remove moisture from the air and in that way, to protect the inventory from the damaging effects of moisture and to prevent the high-priced materials’ destruction caused by bacteria, molds, and corrosion. Installation is made in the warehouse or any other preferred location, provision of air flow (or the use of outdoor air as the source of the reactant), changing of filters at intervals, checking the water level, and therefore, keeping the unit serviced and maintaining according to the manufacturer’s manual are the procedures that guarantee the safety of use of commercial dehumidifiers in storage facilities, big halls, and other open or semi-open-air places.

What safety considerations should I know about using an industrial dehumidifier in different industries?

If you use an industrial dehumidifier somewhere from manufacturing to business operations, then don’t just fixate on its benefits. Have in mind the risks connected to electricity connections, the need for a water drainage system, and maintaining a balance between the dehumidifier’s capacity and the moisture and humidity levels present. Places like food plants, hospitals, and manufacturing lines demand the use of models that are made of food-grade or medical-grade parts. The dehumidification operation should not be in any way harmful to the hygroscopic or temperamental materials, and the specific features of the unit, like the desiccant material versus the refrigerant dehumidifiers, should be what you are looking for for your needs.

Is it possible that refrigerant dehumidifiers may pose a fire risk or any other problem when used in an environment with low temperatures and high humidity levels?

In case the airflow is blocked, dust builds up, or the system is misused, refrigerant dehumidifiers may suffer from overheating, but the present models already have the overheating prevention mechanisms inbuilt. When the air is cold, and the outdoor temperature is so low that the coils become very cold, cold areas may not be the best spaces for these units, leaving aside the low efficiency and icing, the latter being a possible malfunction cause if not corrected. Desiccant technologies, however, are in their element in cold weather. Not only do the proper operation and safety of the system benefit from this efficient use of energy resources, but also the latter in itself.

How do the industrial air dryers work, and what is the safety level of the dehumidifying process?

Industrial dehumidifiers work by eliminating the dampness in the air through two methods: either by cooling the air over a refrigerant coil (refrigerant dehumidifiers) or through the adsorption of water by the desiccant materials. If the units are sized and operated properly, the dehumidification process would be safe, with filters and reservoirs being cleaned continually, condensate being properly drained, and the unit being checked for any refrigerant leak. In addition to this, safe disposal of condensate and following the manufacturer’s safety protocols will greatly minimize any risks associated with improper use of the unit.

Can it be affirmed that health problems arising from the presence of mold and dust mites may be effectively prevented with the help of industrial dehumidifiers?

Industrial dehumidifiers are invariably in place in a lot of settings where high humidity is a problem that brings with it manifold health issues like allergic reactions from dust mites, increased bacterial growth, and mold. The dehumidifiers, by keeping the air dry and the moisture level reduced, make the environment a lot healthier and more comfortable, especially in locations like healthcare facilities, food processing plants, or any kind of area with humidity issues that carry health or contamination risks.

Does the dehumidifier come with some sort of safety lockout system so there are no instances of water spilling, reservoir overflow, or energy going to waste?

Sure, most of the dehumidifiers for industrial use would have a range of safety features for their customers, among which one could expect full-reservoir shutoff, automatic condensate pumps, overflow alarms, and low-temperature defrost cycles. The two main factors that can help the dehumidifier to be more energy-efficient and prevent it from unnecessary operation are the energy-saving controls and adjustable humidistats. If all the safety features are synchronized with one another and working perfectly, then the dehumidifiers will not be a cause of trouble, such as spills or excessively high energy consumption, provided they are correctly positioned and regularly checked.

Do industrial dehumidifiers have the capability to work safely in a food processing plant or production process environment?

Industrial dehumidifiers may be operated in food processing plants and production process environments when you use units specially made for those tasks that minimize the very low risk of contamination and meet the cleanliness requirements. Units should nullify the possibility of wetness coming into contact with surfaces, keep the ambient air less wet according to the established range, and avert pollutant entry. Regular cleaning, right drainage, and compliance with the requirements keep both the product and human health safe.

What could happen if I didn’t choose the right industrial dehumidifiers, and how would I know I made the right choice?

Choosing incorrect industrial dehumidifiers poses great dangers of not solving the moisture problem adequately, wasting a lot of energy, and even causing some equipment to wear out faster or overheat, and affecting the sensitive materials. A thorough evaluation of the area to be dehumidified, required humidity level, ambient temperature, and precise demands of the place—like if the dry air gets re-warmed or hygroscopic materials are present— will help in making a safe selection. The manufacturers’ opinions about the machine’s capability and the comparison of energy efficiency ratings should also be the factors looked at before maintenance planning takes place in your project. This will assist in zeroing down to a device that will perform scrupulously in eliminating the humidity issue and safeguarding both property and people.