When it comes to disposing of old appliances like dehumidifiers, many people don’t realize the potential environmental impact tied to the refrigerants they contain. One common question that arises during this process is, “Do dehumidifiers contain Freon?” If you’re preparing to replace or discard your dehumidifier, understanding whether it includes this refrigerant—or any other type of refrigerant—is crucial. This article dives into the role refrigerants play in dehumidifiers, why proper disposal is essential, and how you can take the necessary steps to ensure compliance with environmental standards. By the end, you’ll be equipped with the knowledge to manage your appliance responsibly while safeguarding the environment.

What Type of Refrigerant Do Dehumidifiers Use?

Dehumidifiers commonly use two types of refrigerants: R-410A and R-134A. These refrigerants are specifically designed to facilitate the cooling process necessary for moisture removal from the air. R-410A is widely used in modern appliances due to its energy efficiency and eco-friendlier properties compared to older refrigerants. R-134A, while still effective, is often found in smaller or older models. Both types help the dehumidifier perform efficiently, but it’s important to handle them carefully and comply with environmental disposal regulations when disposing of the appliance.

Common refrigerants in dehumidifiers: Freon vs alternatives

Freon was once the dominant refrigerant used in dehumidifiers due to its effectiveness in removing moisture and regulating air temperature. However, Freon, which includes chemicals such as R-22, has been phased out in many regions due to its harmful effects on the ozone layer. The Montreal Protocol, an international treaty adopted in 1987, led to the gradual reduction and eventual ban of ozone-depleting substances, including R-22 Freon.

Modern alternatives, such as R-410A and R-290, have replaced Freon in many appliances. R-410A is a hydrofluorocarbon (HFC) that does not contribute to ozone depletion, although it still has a Global Warming Potential (GWP) of 2088. It is widely used in newer dehumidifiers and air-conditioners due to its high energy efficiency. On the other hand, R-290, a hydrocarbon also known as propane, is gaining traction as an eco-friendlier refrigerant. With an ultra-low GWP of 3 and zero ozone-depleting potential, R-290 represents a significant advancement toward greener solutions.

Industry data reveals that appliances using R-410A can achieve up to 10-15% higher energy efficiency compared to older models with R-22. Meanwhile, R-290 is being adopted in dehumidifiers designed for markets with stringent environmental standards, as its minimal environmental impact aligns with global sustainability goals. While R-290 is highly effective, it is flammable and requires safety considerations during manufacturing and usage.

By transitioning to these modern alternatives, manufacturers are not only reducing the environmental footprint of their products but also aligning with evolving regulatory standards. For consumers, understanding these refrigerants is crucial to making informed choices about appliances that balance performance, safety, and environmental responsibility.

How refrigerants like Freon help remove moisture from the air

Refrigerants, also known as Freon, are vital for moisture removal from air since they aid condensation. When air is blown over the evaporator coils in any air conditioning or dehumidification system, the refrigerant in the coils extracts heat from the air around it to cool to a temperature below its dew point. At this point, vapor moisture turns into water that can be collected or drained away, effectively reducing humidity.

Advanced modern air conditioning units make use of this process efficiently. Most of these newly constructed units can remove several gallons per day, depending on humidity levels, room size, and unit capacity. For instance, some residential units are capable of moisture removal of 20-70 pints daily, helping substantially in humid regions. Furthermore, there is a growing use of low-global-warming-potential GWP refrigerants, which improves environmental impact while dehumidifying air.

EPA regulations and the transition away from CFC refrigerants

The Environmental Protection Agency (EPA) has played a pivotal role in guiding the United States toward the phase-out of chlorofluorocarbons (CFC) refrigerants in alignment with the Montreal Protocol, an international treaty established to protect the ozone layer. CFCs, once widely used in refrigeration, air conditioning, and aerosol propellants, were identified as major contributors to ozone depletion due to their release of chlorine atoms when broken down by ultraviolet light in the stratosphere.

Since 1996, the EPA has implemented strict regulations prohibiting the production and import of most CFCs, leading to a significant decline in their atmospheric concentration. The transition includes the adoption of alternative refrigerants such as hydrofluorocarbons (HFCs), which do not deplete the ozone layer but still have a high global warming potential (GWP). More recently, emphasis has shifted toward the use of next-generation refrigerants like hydrofluoroolefins (HFOs) and natural refrigerants such as ammonia and carbon dioxide, which offer lower environmental impacts and higher energy efficiency.

Studies indicate that the global phase-out of CFCs has led to a recovery of the ozone layer, with projections suggesting it could return to 1980 levels by the mid-21st century. Domestically, regulations enforcing leak-repair requirements, certification for handling refrigerants, and penalties for non-compliance underscore the EPA’s commitment to this transition. These efforts not only mitigate ozone depletion but also contribute to broader climate goals by reducing the GWP footprint of refrigeration technologies.

Do All Dehumidifiers Have Freon or Refrigerants?

No, not every dehumidifier uses Freon or refrigerants. While most conventional dehumidifiers refrigerate the air to dehumidify it, some other types devices exist. For instance, desiccant dehumidifiers capture moisture using absorbent materials, so no refrigerants are required. Such alternatives are commonplace within certain environments, where refrigerants are unnecessary or impractical. These devices effectively control moisture without the use of chemicals like Freon.

Refrigerant dehumidifiers vs desiccant dehumidifiers

When comparing refrigerant dehumidifiers and desiccant dehumidifiers, significant differences in their functionality, efficiency, and ideal applications emerge. Refrigerant dehumidifiers work by drawing air over cold coils, causing moisture to condense and collect in a reservoir. These types are highly effective in warm and humid conditions, typically operating best in temperatures above 60°F (15°C). Modern refrigerant dehumidifiers can extract up to 50-70 pints of moisture per day, making them suitable for residential settings or large humid spaces. However, they may lose efficiency in cooler climates since condensation is less effective when air temperatures are low.

Desiccant dehumidifiers, on the other hand, leverage a moisture-absorbing material, such as silica gel, to pull water vapor from the air. These systems excel in environments with low temperatures or where minimal noise is crucial, as they operate efficiently even below 32°F (0°C). Unlike refrigerant models, they don’t rely on condensation or refrigerants, which makes them lighter, quieter, and better suited to industrial or colder residential applications. However, desiccant models often have lower daily moisture removal capacities, typically ranging from 10-20 pints, depending on the unit size, which can limit their use in highly humid spaces.

Ultimately, selecting the right type depends on environmental conditions and specific needs. Refrigerant dehumidifiers are top-rated for most homes in warm climates or during summer months, while desiccant dehumidifiers are the go-to choice for colder seasons, basements, and industrial storage settings. Modern advancements in both technologies have further enhanced their energy efficiency, making moisture control more sustainable than ever.

How different types of dehumidifiers work

Dehumidifiers operate by extracting excess moisture from the air, but the underlying mechanisms differ by type. Refrigerant dehumidifiers, for instance, use a cooling coil to condense water vapor. Warm, humid air is drawn into the device and passed over chilled evaporator coils, causing the moisture to condense and drip into a collection tank. These models function optimally in environments with high temperatures and humidity levels, as their performance tends to decline in cooler settings.

On the other hand, desiccant dehumidifiers rely on a hygroscopic substance, such as silica gel, to absorb moisture. Air passes through the desiccant material, which traps the water vapor. A built-in heater periodically dries the desiccant, allowing it to be reused. This mechanism works efficiently in colder climates or conditions where maintaining low humidity is critical, such as in basements or industrial storage spaces. For instance, desiccant dehumidifiers can reduce moisture levels to as low as 20-30% relative humidity, which is ideal for sensitive materials.

Efficiency has significantly increased in both types due to modern technological advancements. For example, Energy Star-rated refrigerant dehumidifiers are now 30% more efficient on average than conventional models, saving both energy and operating costs. Similarly, many desiccant models now feature more sustainable heating elements, such as ceramic or PTC (Positive Temperature Coefficient) heaters, which consume less energy while maintaining powerful moisture removal capabilities. Choosing the right type depends heavily on environmental factors and specific use cases, with current innovations ensuring users can find a dehumidifier tailored to their needs.

Identifying if your dehumidifier uses refrigerant

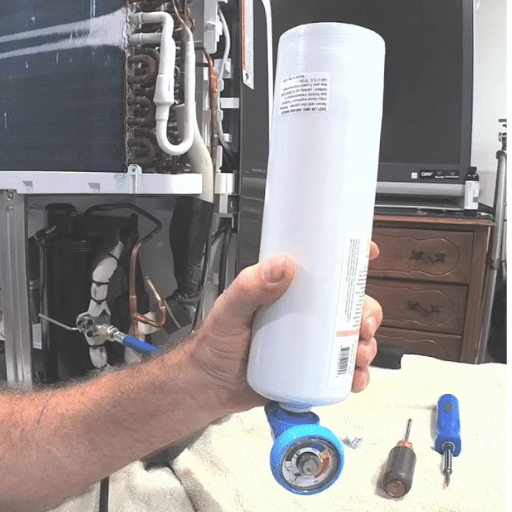

To determine whether your dehumidifier uses refrigerant, you can start by examining key components and features of the device. Most refrigerant-based dehumidifiers, also known as compressor dehumidifiers, include a compressor and refrigerant coils as part of their internal structure. These models function by drawing in humid air, cooling it on refrigerated coils to condense moisture into water, and then reheating the air before releasing it back into the environment. If your dehumidifier produces a noticeable flow of warm air or has a water reservoir that fills regularly, it’s likely a refrigerant model.

Another way to identify refrigerant usage is to check the product’s label or user manual. Look for mentions of refrigerants, such as R-134a, R-410A, or HFOs, which are commonly used substances. Many manufacturers are required by regulations to list these refrigerants on product labels due to environmental standards.

Recent trends in refrigerant dehumidifiers lean toward environmentally friendly refrigerants like R-32 or natural alternatives, which have lower Global Warming Potentials (GWPs) compared to older refrigerants. If determining refrigerant type is a concern, this information is often available in product specifications or detailed on the packaging.

For further confirmation, understanding your dehumidifier’s energy efficiency rating may provide clues. Refrigerant dehumidifiers typically have a higher power consumption compared to desiccant models, especially in cooler environments. Additionally, the presence of frost or ice at very cold temperatures can also suggest the use of refrigerant, as compressor coils may freeze under such conditions.

How Does a Refrigerant Dehumidifier Work?

Refrigerant dehumidifiers operate by pulling in moist air from the environment. The air passes over cold coils containing the refrigerant that reduces the temperature of the air. This results in moisture condensing into water droplets. The water is either stored in a tank, drained away, or removed. The air is then reheated and re-released back into the room. This process keeps repeating until the specific humidity level is achieved. Refrigerant dehumidifiers work best in warm and humid conditions because of their cooling efficiency.

The role of the compressor and refrigerant in dehumidification

Dehumidification is done right with the help of the refrigerant and compressor working together to eliminate moisture. The first step in the process begins with the compressor, which does the job of compressing the refrigerant giving a boost to its temperature and pressure. From there, it moves to the condenser coils, where heat is exchanged, and is then transformed into a cool high pressure liquid.

The dehumidifier brings in moisture-filled air which then moves over the evaporator coils cooled by the refrigerant. Those coils breeze dry air that is cooled to well below the dew point, causing vapor in the surrounding humid air to condense into liquid water. The water is pumped out while the dry air is released into a tank. Moreover, it’s expelled through a drainage system. The air is then used to raise all surfaces in the room. This removes coolness and produces warmth while moderate elevation makes sure the temperature is comfy not too low.

Along with eco-friendly refrigerants such as R-410A and R-32, modern compressors are utilized in an environmentally conscious manner. This upgrade ensures that dehumidifiers operate with maximum efficiency and minimum impact on the environment. A case in point, R-32 is preferred over older refrigerant R-22 due to its 68% lower global warming potential (GWP). Many new models offer energy efficiencies of 1.5 to 2.2 liters per kilowatt hour (L/kWh) which measures the amount of electricity needed to remove significant moisture.

Similarities between dehumidifiers and air conditioning systems

Dehumidifiers and air conditioning systems share fundamental similarities in their mechanisms and purposes, as both are designed to regulate indoor air conditions for enhanced comfort and efficiency. At the core of both systems lies the process of condensation, where warm, moist air is drawn into the unit and passed over refrigerant-cooled coils. This process cools the air, causing moisture to condense into water droplets, which are then collected or drained away. The now drier air is then reheated slightly and circulated back into the room.

Both devices incorporate components such as compressors, evaporator coils, and condensers, which play essential roles in the cooling and dehumidifying processes. For instance, advanced compressors in modern units are engineered to operate with minimal energy consumption, enhancing sustainability. Additionally, both systems contribute to improved indoor air quality—dehumidifiers by reducing humidity levels that promote mold and mildew growth, and air conditioning systems by filtering airborne particles as they cycle the air.

Energy efficiency is another notable similarity. Technological advancements have allowed manufacturers to improve efficiency ratings for both dehumidifiers and air conditioners, measured by metrics such as the Energy Efficiency Ratio (EER) or Seasonal Energy Efficiency Ratio (SEER). Many of these systems now feature smart functionalities, enabling users to optimize performance while minimizing energy costs.

Importantly, maintaining proper humidity and temperature control through these systems not only provides comfort but also protects sensitive materials and electronics from moisture damage, highlighting their critical roles in residential, commercial, and industrial settings.

Why refrigerants are effective at controlling humidity levels

Refrigerants play a crucial role in regulating humidity levels through their ability to absorb and release heat within HVAC systems. When air passes over the evaporator coil, the refrigerant inside the coil absorbs heat and causes water vapor in the air to condense, effectively removing moisture. This condensation process is a direct result of the temperature of the evaporator coil being lower than the dew point of the surrounding air.

Modern refrigerants, such as hydrofluorocarbons (HFCs) like R-410A, are designed to optimize this condensation process while maintaining environmental standards. For example, studies have shown that high-efficiency systems utilizing advanced refrigerants can remove up to 75–85% of indoor air moisture in humid climates, ensuring a comfortable living environment and protecting indoor materials from excess dampness. Additionally, these systems are energy-efficient and can maintain target humidity levels with fewer energy inputs, thanks to advancements in refrigerant formulas and system design.

By integrating refrigerants specifically engineered for precise heat transfer and moisture removal, HVAC technologies ensure an optimal balance of humidity and air quality for both residential and commercial applications. This capability not only enhances comfort but also prevents issues like mold growth and damage to sensitive electronics, making refrigerants indispensable for effective climate control.

Is Freon in Dehumidifiers Harmful to the Environment?

Freon was a widely used refrigerant in dehumidifiers, but it poses environmental concerns. Its primary impact is potential environmental harm to the ozone layer depletion if released into the atmosphere. Because of this, many types of Freon have been globally phased out under the Montreal Protocol. Newer models of dehumidifiers use refrigerants that are more environmentally friendly. Eco-friendly refrigerants do not harm the environment as much as older refrigerants while still performing the needed functions. To reduce the detriment, owners of older Freon units should have them properly disposed of by certified professionals.

Environmental impact of refrigerants and the ozone layer

Refrigerants, while essential to various cooling and heating applications, have a measurable impact on climate change due to their global warming potential (GWP). Hydrochlorofluorocarbons (HCFCs) and chlorofluorocarbons (CFCs), such as Freon, are known for their ozone-depleting characteristics. When released into the atmosphere, these compounds not only thin the ozone layer but also contribute significantly to greenhouse gas effects. For instance, studies show that HCFCs and CFCs can be thousands of times more potent in contributing to global warming compared to carbon dioxide.

The advent of hydrofluorocarbons (HFCs), designed as replacements for ozone-depleting substances, helped mitigate some ozone concerns but introduced a high GWP, exacerbating climate change. According to data, HFC-134a, a common HFC refrigerant, has a GWP of 1,430 over a 100-year period, compared to carbon dioxide’s GWP of 1. This indicates the urgent need for alternatives that are both ozone-safe and have minimal GWP impact.

With global commitments like the Kigali Amendment to the Montreal Protocol, countries are adopting newer, more sustainable refrigerants. These include natural alternatives such as propane (R-290) and ammonia (R-717), which feature GWP values close to zero. These substances not only mitigate climate risks but also align with a growing trend of environmental responsibility among industries.

Reducing the environmental impact of refrigerants requires ongoing innovation, strict regulation, and education on proper refrigerant handling. Recent advancements in low-GWP technologies are providing hope for a cleaner, more sustainable future, signaling the importance of collective action in addressing this pressing environmental issue.

Modern refrigerants vs older Freon (R-22) types

Modern refrigerants, such as R-410A and R-32, are designed to be more environmentally friendly compared to older Freon (R-22) types. Unlike R-22, which has a high ozone depletion potential (ODP) and contributes significantly to environmental damage, newer refrigerants have zero ODP and lower global warming potential (GWP). Additionally, modern refrigerants are more energy-efficient, improving system performance while reducing emissions. The phase-out of R-22, driven by global agreements like the Montreal Protocol, highlights the shift toward sustainable alternatives that align with today’s environmental standards.

Clean Air Act requirements for refrigerant handling

The Clean Air Act establishes strict guidelines for refrigerant handling to minimize environmental harm and ensure compliance with federal regulations. Section 608 of the Act prohibits the intentional release of refrigerants into the atmosphere, emphasizing the importance of proper recovery, recycling, and disposal practices. Certified technicians must use EPA-approved recovery and recycling equipment when servicing or disposing of air conditioning and refrigeration systems. Additionally, service providers are required to maintain detailed records of refrigerant purchases, use, and recovery to verify compliance.

Recent updates to the Clean Air Act regulations have expanded their scope. These changes now include all substitute refrigerants like HFCs that were not originally covered under the earlier regulations. This shift aims to further limit emissions contributing to global warming.

Facilities with equipment containing refrigerants in quantities above 50 pounds are also subject to mandatory leak inspections and repairs. If leaks exceed a specified threshold—10% for comfort cooling systems or 30% for industrial process refrigeration—they must be addressed within 30 days to avoid additional penalties. Failure to comply with these requirements can result in substantial fines, with penalties exceeding $40,000 per day per violation under recent enforcement updates.

What Are the Alternatives to Refrigerant Dehumidifiers?

Alternatives to refrigerant dehumidifiers include desiccant dehumidifiers and ventilative dehumidification. Desiccant dehumidifiers use materials like silica gel to absorb moisture from the air, making them ideal for colder environments where refrigerant models may be less effective. Ventilative dehumidification systems, on the other hand, rely on increasing airflow and exchanging indoor air with outdoor air to reduce humidity levels. These options are energy-efficient and can be better suited for specific applications or environmental conditions.

How desiccant dehumidifiers work without refrigerants

Desiccant dehumidifiers operate by leveraging the hygroscopic properties of certain materials, such as silica gel or zeolite, to attract and trap moisture from the air. These substances are highly effective at absorbing water vapor due to their chemical structure, which allows them to bind to moisture molecules. When humid air passes over the desiccant material, the moisture is absorbed, leaving the air drier.

Unlike refrigerant-based dehumidifiers, desiccant models do not rely on compressors or refrigerants to cool the air. Instead, they utilize a regeneration process to maintain their effectiveness. The saturated desiccant is heated, typically using an internal heating element, to release the trapped moisture as vapor. This vapor is then expelled outside the dehumidification system, allowing the desiccant to be reused in a continuous cycle.

Desiccant dehumidifiers are particularly efficient in lower-temperature environments where refrigerant models may struggle to perform effectively. For example, research indicates that desiccant dehumidifiers maintain optimal performance even in spaces below 41°F (5°C), making them ideal for use in basements, garages, or colder climates. Additionally, these devices are often more compact and quieter, catering to users who prioritize low noise levels and portability. Their ability to function efficiently without harmful refrigerants also aligns with increasing environmental regulations and sustainability goals.

Comparing refrigerant vs non-refrigerant dehumidifier efficiency

When evaluating the efficiency of refrigerant and non-refrigerant dehumidifiers, it is essential to consider factors such as environmental conditions, power consumption, and moisture removal rates. Refrigerant dehumidifiers excel in warm and humid climates, efficiently removing substantial amounts of moisture. They operate by cooling air to condense moisture, which is then collected in a tank or drained. However, their performance dips significantly in colder environments due to the risk of frost buildup on coils, reducing their energy efficiency.

Non-refrigerant dehumidifiers, such as desiccant models, are designed to perform effectively in a wider range of temperatures, including cold spaces as low as 32°F (0°C). They use hygroscopic materials to absorb moisture from the air, which makes them more consistent in colder conditions. While these models often consume more energy for moisture extraction at higher temperatures, they maintain reliability when ambient temperatures drop, providing steady performance.

Energy consumption is another critical point of comparison. Refrigerant dehumidifiers generally use less energy in warm climates due to their process being optimized for humid conditions. Conversely, desiccant dehumidifiers may require more power in such settings, though their ability to operate without refrigerants contributes to lower environmental impact. For example, energy-efficient models of desiccant dehumidifiers typically meet environmental demands without the use of harmful cooling agents.

According to recent data, a standard refrigerant dehumidifier removes approximately 70 pints of moisture per day in optimal conditions with an energy efficiency ratio (EER) averaging 1.8 L/kWh. On the other hand, high-quality desiccant models are able to remove around 50 pints daily in colder settings, where refrigerant units struggle, with an EER of approximately 1.5 L/kWh in such environments. These figures demonstrate the situational advantages of each type, underscoring the importance of matching the dehumidifier type to specific use cases.

Choosing the right type of dehumidifier for your needs

When selecting a dehumidifier, it’s crucial to evaluate factors such as room size, typical humidity levels, temperature, and energy efficiency. Refrigerant dehumidifiers are typically optimal for warm, humid conditions, making them ideal for use in basements, laundry rooms, and tropical climates. A standard refrigerant model with a capacity of 50 pints can effectively cover areas up to 1,000 square feet with a humidity level of around 60% or higher. These units typically achieve an energy efficiency ratio (EER) of 1.8 L/kWh, ensuring strong performance in suitable environments.

For cooler climates or when relative humidity is lower (around 50%), desiccant dehumidifiers offer advantages. These units excel in temperatures ranging from 33°F to 50°F, where refrigerant models become less effective. A high-efficiency desiccant unit can extract up to 50 pints of moisture per day at an EER of approximately 1.5 L/kWh, ensuring effective damp control in unheated spaces like garages, crawl spaces, or storage areas.

It’s also vital to consider energy consumption, especially for long-term operation. Look for Energy Star-certified models, as they consume less electricity while maintaining performance. For larger spaces exceeding 1,500 square feet, commercial-grade dehumidifiers are recommended. These units can remove between 70 to 120 pints of moisture daily and often include more robust features like continuous drainage, air filters, and programmable settings for flexibility.

Ultimately, selecting the appropriate dehumidifier depends on your specific needs, whether prioritizing high-volume moisture removal, adaptability in colder temperatures, or energy efficiency for everyday use. Ensure that the unit’s capacity matches your room size and humidity demands for optimal performance.

Reference Sources

Frequently Asked Questions (FAQs)

Q: Do dehumidifiers contain Freon, and how does it affect disposal?

A: Many older dehumidifiers use Freon, a type of refrigerant gas, which can impact the disposal process. It is important to know how to dispose of dehumidifiers properly, as improper disposal can harm the environment. Newer models may use alternative refrigerants due to Freon being phased out.

Q: How can I dispose of a dehumidifier safely?

A: To dispose of a dehumidifier safely, you should contact a local recycling center or appliance disposal facility. These centers have the proper equipment to handle refrigerant gases and can ensure the dehumidifier is disposed of in an environmentally friendly manner.

Q: Is it necessary to remove the Freon before dehumidifier disposal?

A: Yes, it is necessary to remove Freon or any other refrigerant gas before dehumidifier disposal. This process should be handled by certified professionals to comply with environmental regulations, such as Section 608 of the Clean Air Act.

Q: What regulations apply to the disposal of dehumidifiers containing Freon?

A: The disposal of dehumidifiers that contain Freon is regulated under Section 608 of the Clean Air Act. This regulation requires the recovery and proper disposal of refrigerants to prevent harmful emissions into the atmosphere.

Q: Can I dispose of my old dehumidifier with regular trash?

A: No, you should not dispose of your old dehumidifier with regular trash, especially if it contains refrigerant gas like Freon. Doing so can lead to environmental hazards and legal penalties. Always use a certified recycling or disposal service.

Q: What is the best way to dispose of a whole-house dehumidifier?

A: A whole-house dehumidifier should be disposed of in the same way as other home appliances that contain refrigerants. Contact a professional appliance disposal service that can handle large units and ensure all refrigerants are properly removed.

Q: Are there alternatives to Freon in new dehumidifiers?

A: Yes, new dehumidifiers often use alternative refrigerants, which are more environmentally friendly. These alternatives have been developed as Freon is being phased out due to its environmental impact.

Q: How do I find a recycling center for dehumidifier disposal?

A: You can find a recycling center for dehumidifier disposal by searching online for local facilities that accept home appliances containing refrigerants. Many municipalities offer resources and guidance on appliance disposal.

Q: Are commercial dehumidifiers disposed of differently than residential models?

A: Commercial dehumidifiers may require specialized disposal methods due to their larger size and capacity. It’s important to consult with a professional disposal service that can handle the unique requirements of commercial units.