Transform rough lumber into works of art while protecting your health and workspace. Discover how professional air filtration systems can revolutionize your woodworking environment, ensuring clean air, enhanced safety, and improved productivity in every project.

Understanding Air Filtration Systems

A shop air cleaner is a specialized system designed to remove dust, particles, and contaminants from woodworking environments. These systems work by drawing contaminated air through advanced filtration stages, capturing harmful particles, and returning clean, breathable air to your workspace.

How Air Filtration Works

Air filtration systems use multiple filtering stages to capture particles of varying sizes. The process begins with pre-filters catching larger debris, followed by high-efficiency filters that remove microscopic particles, and finally specialized filters for odors and chemical vapors.

The Critical Need for Filtration in Woodworking

Woodworking processes like sawing, sanding, and milling generate fine dust particles and potentially toxic chemicals that pose serious health risks. These airborne contaminants can cause respiratory issues, allergic reactions, and long-term health problems while also affecting equipment performance and project quality.

Particle Removal Efficiency

Micron Minimum Size

Energy Savings Potential

Key Benefits of Shop Air Cleaners

Health Protection

Eliminate harmful dust particles, allergens, and chemical vapors that cause respiratory issues and long-term health problems. Create a safer working environment for you and your team.

Enhanced Productivity

Cleaner air means better visibility, reduced fatigue, and improved focus. Workers perform better in environments with high-quality air circulation and filtration.

Equipment Longevity

Protect expensive machinery from dust buildup and corrosion. Clean air extends equipment life and reduces maintenance costs significantly.

Quality Improvement

Dust-free environments produce higher-quality finishes and prevent contamination of your woodworking projects during critical stages.

Compliance Assurance

Meet occupational safety standards and regulations while demonstrating commitment to worker health and environmental responsibility.

Cost Savings

Modern energy-efficient systems reduce operational costs while preventing expensive health-related issues and equipment repairs.

Essential Features of Woodshop Air Filtration Systems

HEPA Filtration

High-Efficiency Particulate Air filters capture 99.97% of particles as small as 0.3 microns, including fine wood dust from sanding and cutting operations.

Activated Carbon Filters

Remove chemical odors and volatile organic compounds (VOCs) from varnishes, paints, finishes, and other woodworking chemicals.

Variable Speed Control

Adjustable airflow rates allow optimization for different activities and contamination levels, from light sanding to heavy sawing operations.

Smart Technology Integration

Modern systems include sensors for automatic operation, mobile app controls, and real-time air quality monitoring for optimal performance.

Energy Efficiency

Advanced motor technology and optimized airflow designs minimize power consumption while maintaining continuous, effective air cleaning.

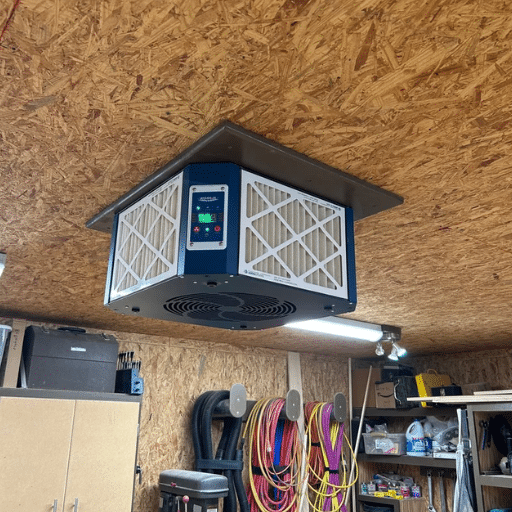

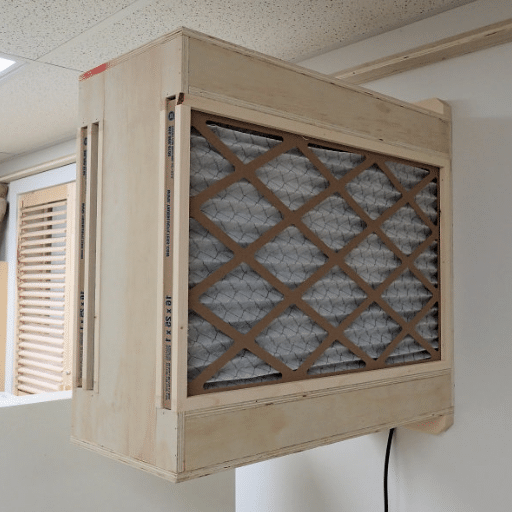

Flexible Installation Options

Wall-mounted, ceiling-hung, or portable units accommodate various workshop layouts and space constraints effectively.

Understanding CFM (Cubic Feet per Minute)

What is CFM and Why It Matters

CFM measures the volume of air an air cleaner can process per minute. This critical specification determines the system’s effectiveness in your specific workspace size and contamination levels.

CFM Calculation Guidelines

| Workshop Size | Recommended CFM | Air Changes per Hour | Typical Applications |

|---|---|---|---|

| Small (up to 200 sq ft) | 200-400 CFM | 6-8 ACH | Hobby woodworking, small projects |

| Medium (200-500 sq ft) | 400-800 CFM | 6-8 ACH | Professional workshops, furniture making |

| Large (500-1000 sq ft) | 800-1500 CFM | 6-8 ACH | Commercial operations, multiple machines |

| Industrial (1000+ sq ft) | 1500+ CFM | 8-12 ACH | Manufacturing facilities, production lines |

Types of Filters in Air Cleaning Systems

HEPA Filters

Efficiency: 99.97% of particles ≥ 0.3 microns

Essential for capturing fine wood dust, pollen, and microscopic particles. Ideal for allergy sufferers and respiratory protection.

Activated Carbon Filters

Specialty: Chemical odors and VOCs

Remove volatile organic compounds from finishes, adhesives, and solvents. Often combined with other filter types for comprehensive protection.

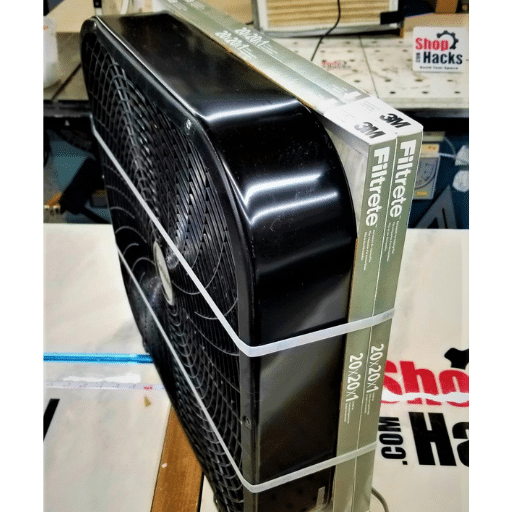

Pre-Filters

Function: Large particle capture

First line of defense against sawdust, wood chips, and debris. Extends life of downstream HEPA and carbon filters.

UV-C Light Filters

Target: Bacteria, viruses, mold spores

Ultraviolet sterilization eliminates biological contaminants, providing additional protection in humid workshop environments.

Electrostatic Filters

Method: Electric charge attraction

Use electrical charges to attract and trap particles. Washable and reusable, making them cost-effective for continuous operation.

Ionic Filters

Process: Negative ion generation

Release negative ions that bind with airborne particles, causing them to settle. Effective for dust and allergen reduction.

Choosing the Right Shop Air Cleaner

Selection Factors to Consider

Choosing the optimal air cleaner requires careful evaluation of your workshop size, typical dust generation, noise tolerance, and specific filtration needs. Consider both current requirements and future expansion plans.

Workshop Size and Layout Considerations

Your workshop’s dimensions and configuration significantly impact air cleaner selection. Larger spaces require higher CFM ratings and potentially multiple units for optimal coverage. Consider ceiling height, equipment placement, and air circulation patterns when planning installation.

| Factor | Small Workshop | Medium Workshop | Large Workshop |

|---|---|---|---|

| Size Range | Under 200 sq ft | 200-500 sq ft | 500+ sq ft |

| CFM Requirements | 200-400 CFM | 400-800 CFM | 800+ CFM |

| Installation Type | Portable or wall-mounted | Ceiling-hung preferred | Multiple units or industrial system |

| Filter Type Priority | HEPA essential | HEPA + Carbon | Multi-stage comprehensive |

Commercial vs. Residential Air Filtration

| Aspect | Commercial Systems | Residential Options |

|---|---|---|

| Capacity | High-volume, continuous operation | Moderate capacity, intermittent use |

| Filtration Technology | Advanced multi-stage with HEPA, UV, carbon | Basic HEPA or standard filtration |

| Durability | Industrial-grade construction | Consumer-grade materials |

| Cost | Higher initial investment, lower operating cost | Lower upfront cost, higher maintenance |

| Compliance | Meets occupational safety standards | Basic health protection |

Health and Safety Implications

Critical Health Risks of Poor Air Quality

- Respiratory Problems: Asthma, bronchitis, and COPD development

- Allergic Reactions: Chronic exposure to wood dust and chemicals

- Long-term Effects: Potential lung damage and reduced capacity

- Immediate Symptoms: Headaches, fatigue, eye irritation

- Vulnerable Populations: Higher risks for children, elderly, and those with existing conditions

Workplace Safety Enhancement

Professional air filtration systems create safer work environments by removing harmful particles before they can cause health issues. This proactive approach reduces worker sick days, improves productivity, and demonstrates commitment to employee well-being.

Maintenance for Optimal Performance

Essential Maintenance Schedule

Weekly Maintenance

Clean exterior surfaces and intake vents. Check for visible dust accumulation and ensure proper airflow around the unit.

Monthly Maintenance

Vacuum pre-filters and check fan blades for dust buildup. Inspect all connections and mounting hardware for security.

Quarterly Filter Replacement

Replace standard filters every 3-6 months depending on usage intensity. HEPA filters may last 6-12 months with proper pre-filtration.

Annual Professional Service

Complete system inspection, motor lubrication, electrical connections check, and performance testing by qualified technicians.

Filter Replacement Guidelines

| Filter Type | Replacement Frequency | Signs for Replacement | Cost Considerations |

|---|---|---|---|

| Pre-Filters | Monthly to Quarterly | Visible dirt, reduced airflow | Low cost, frequent replacement |

| HEPA Filters | 6-12 months | Pressure drop increase, efficiency loss | Higher cost, longer intervals |

| Carbon Filters | 3-6 months | Odor breakthrough, saturation | Moderate cost, regular replacement |

| Electrostatic Filters | Clean monthly, replace annually | Damage to collection plates | Higher initial, lower ongoing costs |

Performance Monitoring Tips

- Air Quality Testing: Use PM2.5 and PM10 monitors to measure effectiveness

- Pressure Differential: Monitor filter pressure drop to determine replacement timing

- Visual Inspection: Regular checks for dust accumulation and system wear

- Energy Consumption: Track power usage to identify efficiency changes

- Noise Levels: Listen for changes that might indicate mechanical issues

Maximizing Long-term Value

Cost-Benefit Analysis

Potential Energy Savings

Equipment Life Extension

Maintenance Cost Reduction

Productivity Improvement

Investing in quality air filtration systems provides substantial long-term returns through reduced health costs, extended equipment life, improved productivity, and lower maintenance expenses. The initial investment is typically recovered within 2-3 years through these combined savings.

References

-

UC Berkeley News: An article discussing DIY air purifiers and their impact during wildfire seasons. This source provides insights into air purification efforts and technologies. Read more here.

-

Purdue University Newsroom: A report on innovative bio-based air filters that could transform air filtration and reduce airborne allergens indoors. Explore the details here.

-

EPA Document: A guide on user-friendly supplied-air respirators for auto refinishing, which includes information on in-line air filtration units for shop environments. Access the document here.

Frequently Asked Questions (FAQ)

Is there any such thing called a shop air cleaner, and how on earth does it function?

A, likewise referred to as shop air cleaners, is the cleanliness of the atmosphere in woodworking areas. shop air cleaner There are different filtration methods, including those with MERV ratings, to help them capture airborne dust, dander and other such materials. Dirty air is taken into the air cleaner via a fan and expelled back into the room but in a very useful state of clean air because it passes through filters hence the air is said to have undergone air cleaning practice.

Is it possible to describe how air cleaning with CFM feature improves the quality of the air?

The CFM which is unelongated as the cubic feet per minute gives the volume of air in terms of utilization of an air cleaner. The bigger the CFM present in the unit due to the intensity of the airflow, the greater the capacity of the unit to carry larger amounts of air, and therefore more dust and other bits, elements and pollutants present in the air, a shop air cleaner with the right CFM rating for the size of the workshop, for the best air quality will take away more air to make the air cleaner in the work shop.

Can I substitute a shop clean up for a dust collection system?

It is possible to use a shop vac as dust collector but it will not be as effective as dust collector in this regard. Shop vacs are portable units, designed for short-time usage, while a dust collector will possess steady company and be able to deal with the vortices made by sanding as well as carving work with ease. In case of long term carpentry work having a good dust control system which is more effective in filtering and circulation of dust can be helpful.

What are the requirements to consider in an air cleaner particularly for woodworking?

In cases of a shop air cleaner that one can purchase, such details include preferences such as a built-in ionizer or a merv rating and the ability to alter the speed along with the amount of intakes and outlets. A filtration system with a 3 speed system where its operation is controlled using a remote is useful, and an intake that can reach all around will improve the effectiveness in collecting dust. Also look at the fan itself for other features like a timer for automatic working and a panel for changing settings easily.

How frequently should I change filters in my shop air cleaner?

Cleaning shop air filters should be considered part of routine maintenance. Check the filters and replace them within 3 to 6 months, or more often if the usage or dust generation in your woodworking shop is excessive. Incorporation of a MERV-11 filter guarantees to up dust collection capability making your shop air cleaner continue to work efficiently by capturing all the particles in the air.

What are the advantages of using a vortex fan in air cleaner?

The vortex fan is a special design which has been developed to increase air flow and thus, make air validation systems more effective. The vortex fan also enhances the process of dust collection by pulling contaminated air and pushing cleansed air more efficiently. This feature is especially useful in areas with a lot of suspended particles such as sawdust in woodworking.

Would it be a wise decision to buy an air cleaner with a cheaper price?

Cheaper shop air cleaner options may lure many customers into buying these devices, however, they rarely produce satisfactory results and do not last long. With this in mind, it is advisable to buy a proven model of a proven name like Powermatic or Jet Air Filtration, which usually offer a better service and performance in the long term. You can usually find one with a good compromise of price and features including MERV level filters and optimal CFM level for the required area.

How does an ionizer built in the equipment enhance the enhancement of the air inside the building?

The purpose of an integrated ionizer is to release positive and negative ions in the air so that any particles which are present in the air become charged and merge together to become heavy enough to fall down. As a result, the quality of air in terms of possible pollutants like dust and other allergens improves. Adding a built-in ionizer feature to an air cleaner for use in woodwork carpentry shops enhances the efficiency of the typical filtering system.

Any importance of having both filters in itself along with the main filter?

Filters, when integrated inside together with outer ones, make the air cleaner more efficient generally. The outer layer usually traps big particles whereas the inner layers trap smaller ones that may be dangerous to an individual’s health and has higher MERV rating. Because of such dual filters, most of the dirt and dust particulates will be filtered out, leaving your workshop with clean air.