Desiccant dehumidifiers are advanced tools integrated for effective moisture control in different environments. These systems do not use refrigerants; instead, they use hygroscopic substances called desiccants and pull humidity directly from the atmosphere. They are invaluable in applications where traditional dehumidification techniques are ineffective due to low temperatures and specific moisture levels. This article is structured to give the reader an understanding of how desiccant dehumidifiers operate alongside their strengths in the industry and homes. Readers will have a rounded appreciation for the need for desiccant dehumidifiers as a core element for maintaining standard air quality without excessive humidity to prevent damage.

What is a desiccant dehumidifier and how does it differ from refrigerant models?

Desiccant dehumidifiers operate without a cooling cycle, which enhances performance in environments with low temperatures and humidity. Instead of refrigerants like other models, a Silica gel is used, which acts as a hygroscopic substance and absorbs moisture. This distinctive feature makes them less heavy and noisy, enabling their use in environments with drastic changes in conditions. These specific applications allow for specialized processes and industries to function more efficiently.

An introductory look at desiccant dehumidification

To manage air moisture effectively, desiccant dehumidification employs the distinctive qualities of hygroscopic substances. Its operating principle begins with the air passing through desiccant gel, usually wrapped in a silica membrane that contains water vapor within its pores. When the gel desiccant is saturated, it can be heated, which drives off the water vapor and makes it ready for further use. These types of dehumidifiers are evaluated using key technical parameters, such as moisture removal efficiency in grams or liters of water per hour and their regeneration energy in kilowatts (kW). They provide these benefits in areas where refrigerant types of dehumidifiers have severe limitations in maintaining temperatures over 5 deg C and relative humidity lower than 10-20 %. They are essential in the industrial operations of pharmaceuticals, electronics, and processed foods due to their efficiency and flexibility.

Major distinctions between desiccant and refrigerant dehumidifiers

There are two types of dehydrators: desiccant dehumidifiers and refrigerant dehumidifiers. Both serve a specific purpose and operate differently. Desiccant dehumidifiers are ideal for low temperatures and low moisture levels since they employ hygroscopic materials to absorb water. Other crucial parameters include maximum moisture removal and kilowatt energy expenditure. Due to their efficiency in keeping relative humidity at 10%, these systems are perfectly suited for sensitive pharmaceutical or semiconductor production processes.

Refrigerant dehumidifiers, on the other hand, condense water vapor by cooling air until it reaches the dew point with the help of a refrigeration cycle. They function best when the temperature is above 5 degrees Celsius. Power consumption and rated capacity are the other crucial parameters. Refrigerant dehumidifiers are cost-efficient and, therefore, widely used across households, commercial buildings, and manufacturing industries.

Benefits of harnessing desiccant technology for moisture control

For instance, desiccant technology competes favorably in moisture control for such aspects as environments where extremely low humidity is required. These systems can work effectively under a broad range of temperatures, including colder temperatures where refrigerant-based systems are less effective. Such systems also allow for better control over relative humidity which is critical in applications such as food processes, electronic components, and pharmaceutical production. Moreover, there is no heavy reliance on condensation which makes desiccant units very effective in removing moisture from the air which, in turn, decreases the risk of ice formation in the lower temperature environment. These desiccant systems are robust and designed to be adaptable, which ensures that they consistently perform in challenging industrial needs.

How does a desiccant dehumidifier actually remove moisture from the air?

The desiccant dehumidifier employs silica gel to extract water vapor from the air. It pulls air into the dehumidifier, which then circulates past the hygroscopic material that traps moisture. Once the material is saturated, it gets heated in a different chamber, which expels the absorbed moisture. Because these devices do not rely on either condensation or refrigeration, this process allows for a virtually constant low humidity level to be kept, even in cold or low-temperature environments.

The importance of the desiccant materials for humidity absorption

With their hygroscopic nature, desiccant materials can effectively absorb unwanted humidity. Water vapor can easily be attracted and securely held on to. Silica gel is one of the most used desiccant materials due to its comparatively large surface area and strong affinity to water. At certain temperatures and relative humidity, silica gel can adsorb as much as 40% of its weight into water. Other types of desiccant materials that are commonly used include activated alumina, which has good thermal stability and typically operates at -40°F to 500°F. In industrial use, molecular sieves are also common because of their ability to provide specific control of moisture since they have uniform pores that only allow water to enter at lower levels of humidity. These materials are effective in dehumidifiers that function as a desiccant because they can work alternately by absorbing and regenerating the desiccant material, working through a large range of environmental conditions while ensuring the indoor air quality remains optimal.

Function of the Desiccant Wheel

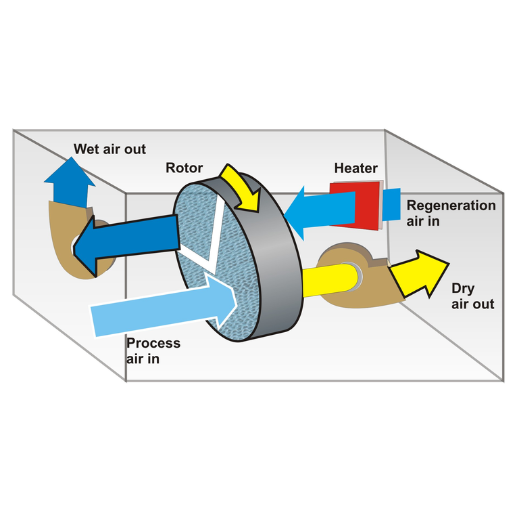

As one of the main parts of desiccant dehumidifiers, the desiccant wheel serves the primary purpose of moisture adsorption and the desiccant regeneration. It constantly rotates and has a coating of desiccant material like silica gel or molecular sieves that capture moisture from the air that passes through it. During operation, air is separated into process and regeneration streams. The process air gets humid air and passes it through the desiccant wheel where the desiccant adsorbs the moisture, thereby drying the air significantly.

A regeneration phase comes next to maintain operational effects. In this, heated regeneration air passes through the wheel, which desorbs the adsorbed moisture and brings the desiccant back to the state where it is ready for usage again. The wheel constantly alternates between the two streams allowing for constant performance. Some key technical parameters include air temperature during regeneration, typically from 93 to 176 degrees centigrade, and the wheel’s speed, which is usually between 10-20 revolutions per hour to allow for moisture removal and regeneration. These figures ensure that reliable and energy-efficient performance is at various conditions.

The techniques employed for moisture regeneration and removal

The dew removal in a desiccant wheel is conducted by adding heated air to release moisture retained by the desiccant material. It refreshes the wheel’s adsorption ability during the process, making it ready again for continuous operations. This process is often done at 200°F and 350°F as these allow the material enough energy to displace moisture while at the same time not degrading the desiccant. The most important components influencing this process are the rates of airflow and temperature accompanying the regeneration phase as both are significant for adequate recuperation efficiency and energy utilization.

Moisture removal, or desorption, mainly depends on the altitude of the process air’s initial humidity, temperature, and the desiccant’s specific volume. The moisture wiper wheel operates at a rotational speed of 10 – 20 revolutions per hour, effectively balancing the adsorbing and regenerating functions for moisture removal. With these parameters set, the system can operate at its full capacity because moisture removal is done without localized oversaturation and energy wastage. However, accurate calibration to match these conditions can be a challenge to align the pillars with performance requirements and environmental factors.

What are the ideal conditions for using a desiccant dehumidifier?

In spaces where temperatures are lower than 60°F and humidity is greater than 45%, desiccant dehumidifiers show their real power. For example, in places such as garages, crawl spaces and basements. Desiccant dehumidifiers, because they can operate efficiently at lower temperatures, work well in areas that are difficult to heat or regulate environmental controls such as Dew point. They also perform well in specific moisture extraction applications with constant airflow and highly humid environments.

Performance in low temperatures

Using desiccant materials such as silica gel in the air makes desiccant dehumidifiers operate effectively at low-temperature environments. They do not rely on condensation and can absorb moisture through a chemical reaction. As the temperature drops, they become much more efficient than refrigerant dehumidifiers. Silica gel is commonly wrapped in filters as it makes the air dry and low in humidity. For places like cold basements or industrial settings, they are highly effective. They also help because, in low temperature settings, they do not form ice that decreases their effectiveness.

Effectiveness at different relative humidity levels

The performance of desiccant dehumidifiers is claimed to be effective at varying degrees of relative humidity (RH) due to their moisture absorption characteristics. In contrast to the refrigerant dehumidifiers, which condense and suffer decreased efficiency with lower RH, desiccant systems use materials that hygroscopically absorb water vapor even when the ambient air is dry with less moisture content < 30% RH. Specialized applications such as preservation, climate-controlled storage, and some industrial processes require that the materials be kept at certain humidity levels, and this ability is valuable in such cases.

Desiccant dehumidifiers also reliably achieve the desired results at higher relative humidity levels where moisture-absorbing materials do not return to the saturation point. Silica gel, for di, is a very common desiccant that can physically scale up to 40% of its mass with the addition of water content and invariably removes water vapor without heating it. This guarantees that moisture levels do not interrupt performance whether it is high, medium, or low. However, desiccant materials above 80% RH require additional energy to heat and change the desiccant while regulating operational efficiency, resulting in partial performance. This is avoided in modern models with adequate built-in regeneration cycles to ensure stable performance and high availability.

Because they can provide environmental stability even when humidity varies significantly, desiccant dehumidifiers are unrivaled in effectiveness and flexibility. In fact, they are favored in situations where standard systems do not work well.

Desiccant Dehumidifiers Best Suited For

- Cold Storage Facilities: These types of dehumidifiers are particularly adept in cold storage. They can function under low temperatures and eliminate frost and surface condensation while keeping the humidity constant, which allows the stored products to retain their quality.

- Pharmaceutical and Medical Industries: Medicines, vaccines and other sensitive products need to be stored under precise environmental conditions so that they do not lose efficacy and potency. In addition, during the production phase, the equipment also requires an optimal environment set by the desiccant dehumidifier for processes such as capsule filling or tablet coating.

- Food Processing and Packaging: The desired environmental conditions for food processing and packaging are free from moisture and excess humidity. Their existence can also lead to clumping, increased microbial growth, and product spoilage which are all big concerns during the intricate processes of drying ingredients while also ensuring hygiene.

- Industrial Manufacturing: The efficiency and deficiency of some manufacturing techniques, such as chemical processes, electronics assembly, and others, such as powder formulation, greatly depend on controlled humidity levels. This is to reduce moisture damage.

- Archives, Museums and Libraries: Artworks, documents, and historical pieces are preserved in a climate-sensitive area where the art is carefully protected from mold, mildew, and even warping through the use of a desiccant dehumidifier.

- Marine and Shipping Industries: Desiccant dehumidifiers are used to prevent rust or corrosion of items inside shipping containers and even equipment on the ship. These devices perform well in dry, wet, or salty conditions, ensuring the items are not harmed even after long periods at sea.

- Cleanrooms and Data Centers: Critical environments like data centers and cleanrooms require perfect humidity levels to function, and these areas are targets for desiccant dehumidifiers. These dehumidifiers help maintain a steady set of conditions to protect electronics from static damage.

- Military and Aerospace Storage: Sensitive equipment such as weapons systems and aircraft parts are stored for long periods of time, but in conditions where they are likely to get corroded and non-functional. Dehumidifiers are the answer to avoiding such damage by removing static in extreme or fluctuating climates.

How efficient are desiccant dehumidifiers compared to other types?

Desiccant dehumidifiers are more effective and economical for regions with low temperatures or humidity dehumidification requirements. Unlike refrigerant dehumidifiers, which utilize condensation to function and work optimally in high temperature settings, desiccant based dehumidifiers work effectively in various conditions due to their use of absorbent materials for moisture capture. Furthermore, because of their ability to dehumidify spaces with low humidity conditions, they tend to draw less energy, giving them an edge in industrial, commercial, and other specialized domains. Their superior performance is also evident in spaces that require a certain level of humidity by reducing the need for maintenance and the downtime of systems over a long period.

Energy consumption and operating costs

The need to regenerate the desiccant materials used increases the energy usage in desiccant dehumidifiers compared to refrigerant models. Yet, in sensitive environments where moisture control is paramount for avoiding dangers like mold, corrosion, and damage, the operating costs are worth it. Even though desiccant-based dehumidifiers tend to require more energy, their efficiency in low temperature and low humidity settings makes them more economically favorable in industrial and specialized situations.

Measuring the efficiency of a dehumidifier

Pint ratings per day is a way to measure the amount of moisture removed within a day. To put it differently, how many pints of moisture a dehumidifier unit is able to extract in a 24-hour setting? By extracting more rates, a unit is more suitable for gravity or humid regions as higher pint ratings typically mean a greater capacity. Always remember that factors like temperature and humidity affect its performance in pints per day. Using granite will also cause the pint rating to deviate from the refrigerant models since its performance is improved at lower temperatures and low humid conditions. It is also paramount to note that compatibility with specific units’ conditions guarantees effective service and energy efficiency.

Long-term efficacy and upkeep planning

I focus on factors like filter replacement, cleaning schedules, and operational lifespan when considering long-term performance and maintenance. Regularly cleaning or replacing air filters ensures the dehumidifier operates efficiently and avoids the buildup of dust and allergens. Desiccant dehumidifiers may require periodic inspection of rotor materials to maintain effectiveness, while refrigerant units benefit from coil cleaning to prevent corrosion or blockage. Additionally, I monitor drainage systems, ensuring continuous operation by keeping hoses and water reservoirs clear of obstructions. Proactive attention to these elements minimizes wear and increases the unit’s durability.

What types of desiccant dehumidifiers are available for home use?

Dehumidifiers meant for home use are categorized relative to their size and the amount of moisture they can extract. Portable compact units are best for smaller locations like bathrooms and closets because they are easy to move around and simple to operate. Mid-sized units are useful for needing moisture control for bedrooms and living rooms. They also come with advanced settings and higher power for efficient moisture extraction. For big spaces or severe humidity problems, whole home dehumidifiers incorporate with HVAC systems or can stand alone, ensuring all areas of the house are maintained within balanced humidity levels. Each category of dehumidifier is designed for different cases of humid control in a residential house to ensure effectiveness and efficiency.

Alternatives of Rechargeable or Disposable Desiccants

Options such as rechargeable and adjustable desiccants are more economical, as well as, environmentally friendly because they can be reused by heating or plugging them into a power source. They do, however, work best in environments where there is a constant need for humidity regulation. In contrast, disposable types are easy to use and do not need any servicing, which greatly benefits temporary measures or in locations where power isn’t accessible. The downside to disposable is that they create more waste and becomes relatively expensive if used for longer periods. The best option greatly varies between scenarios and to which extent the user needs relief from humidity.

Consideration for Sizes in Household Situations

To eliminate all possible excess moisture from a home, a dehumidifier is necessary. Knowing the square footage of the space and the amount of moisture within it will greatly help in selecting the correct capacity dehumidifier, which is measured in pints per day. Most homes typically have a capacity between 20 and 70 pints per day. Dehumidifiers typically have a set amount of moisture they can run through, and this amount is termed PPD.

A twenty-to-thirty PPD unit is usually adequate for smaller areas, such as bathrooms and cupboards. Devices that emit thirty-to-fifty PPD are needed in rooms that are larger in size, such as bedrooms and sitting rooms with square footages of five hundred to fifteen hundred. Places with a square footage of two thousand or more or extremely humid environments often require devices rated over fifty PPD.

Other factors, such as the room’s ambient temperature, ventilation, and humidity, are important to consider as well. For example, models with a higher capacity are often needed for basements due to the excess moisture in the air. Technical performance parameters must be aligned with AHAM (Association of Home Appliance Manufacturers) requirements so the selected unit can achieve the necessary tasks under the real life conditions of the unit.

Aspects to take into account for home use desiccant dehumidifiers

Some of the most significant aspects of a home’s desiccant dehumidifier are its energy consumption, noise level, and how much active work it does. Energy-saving models are comparatively affordable in the long run as they use power carefully and maintain moisture effectively. Having a quieter machine is beneficial while sleeping in a bedroom or working in a living space. Moreover, a unit that has a more adjustable humidistat gives greater versatility to the user by allowing him to set different humidity goals for different situations. It is important to have such features incorporated in such compact, lightweight designs which must also be easy to maintain such as removable and washable filters that can lengthen the device’s lifespan. More sophisticated models might also offer features like automatic shutdown and digital controls, which increase ease of use.

How do you maintain and optimize a desiccant dehumidifier’s performance?

As with any device, the desiccant dehumidifier requires regular maintenance to function optimally. Start with ensuring that the air filters are unblocked or changing them where necessary as their effectiveness is critical to efficiency. Reservoirs or drainage systems meant for water collection also have to be checked and cleaned periodically to prevent mold and bacteria growth. Look for impediments such as dirt and dust that can be stuck in intake and exhaust vents. Additionally, for optimal air circulation ensure that the unit is not kept next to walls or obstructions. Finally, set the unit’s operating range by the manufacturer’s settings, as these need to be adhered to for normal operation. To increase the life of the unit, routine inspections of all components should be conducted, and any wear and tear should be repaired before they become problematic.

Maintenance and Cleaning Advice for Desiccant Units

Noteworthy is the fact that cleaning procedures for a desiccant dehumidifier are as important as caring measures as impeded cleanliness negatively impacts the life span as well as the overall quality of the device. Start with regular cleaning of the air filters since dirty filters are likely to restrict airflow and less optimal system performance is expected. Many units operate with a change of filter after every 1 to 3 months depending on the level of use and the environmental conditions. Make sure that the water tank or the drainage system is inspected every week to detect blockage and be sure that it is cleaned at least once a month by a weak disinfectant so that bacteria do not form. Remove excessive dust from the rotor part that contains the desiccant material. This might be done with the assistance of a service expert so as to avoid damage.

Monitor the environment where the device is located, including the temperature and humidity index. Most of the units are created to perform rather well in a temperature range of -1 to 40 degrees celsius, though some models may indicate upper or lower ranges. Ensure that no obstructions near the machine or walls could restrict the airflow around the unit. A distance of 12-24 inches from the device to other structures is often suggested to allow proper ventilation. Other than these steps, it may be useful to check from time to time, the seals as well as the ducts and the connection joints for any wear and tear or abnormal looseness for proper functioning. Following these measures, proper working conditions and even the device’s life expectancy will be improved.

Replacing or Recharging Desiccants

The nature of the equipment in use typically dictates when desiccant materials are replaced or recharged. It is very convenient for rechargeable desiccants since the material can simply be dried by heating it to a specified temperature, which is often offered in the manufacturer’s instructions. This heightens the desiccant’s ability to dehumidify by removing the water that was already trapped in the material. Non-rechargeable desiccants tend to have a limitation where, after the material becomes saturated, it goes through an ineffective state. Some desiccants employ chemical reactions as a method of removing moisture and once all the chemical is expended the desiccant is no longer useful and should be replaced. Proper procedures regarding installations should always be adhered to in order to maintain the functionality of the equipment and ensure proper compatibility with the machine.

Desiccant Dehumidifiers’ Common Issues

The initial concern is ensuring the unit is powered and plugged in, as it might not turn on. Then, check whether the fuses are blown or there are any tripped circuit breakers. They often don’t perform as well as they should, so keep the air filters clean, as they’ll make the airflow more efficient. Also ensure the desiccant rotor is working correctly, though it might have to undergo maintenance after some use. A simple recalibration will suffice for an unresponsive humidistat, though it could need replacement. If there is excessive noise, the fan and other components must be inspected for any obstruction and misalignment. Finally, the user must consider the manufacturer’s instructions to fix device-specific issues.

Reference sources

Frequently Asked Questions (FAQs)

Q: How does a desiccant dehumidifier work?

A: A desiccant dehumidifier works by using a rotating desiccant wheel coated with a moisture-absorbing material, typically silica gel. As humid air passes through the wheel, the desiccant absorbs moisture from the air. The wheel slowly rotates through a heating section, where warm air is used to remove the moisture from the desiccant, which is then collected in a water tank or drained away. This process allows the desiccant to continuously absorb moisture, effectively dehumidifying the air without the need for a compressor.

Q: What are the advantages of using a desiccant dehumidifier for home?

A: Desiccant dehumidifiers offer several advantages for home use. They operate efficiently at lower temperatures, making them ideal for cooler environments. Unlike conventional dehumidifiers, they don’t use a compressor, resulting in quieter operation. Desiccant dehumidifiers are also effective at achieving very low humidity levels, which is beneficial for preventing moisture damage in sensitive areas. Additionally, they tend to be more energy-efficient and can be lighter and more portable than compressor-based models.

Q: How do desiccant dehumidifiers compare to conventional dehumidifiers in terms of performance?

A: Desiccant vs conventional dehumidifiers differ in their performance characteristics. Desiccant models excel in cooler environments (below 65 degrees F) where they can continue to absorb moisture effectively. They can achieve lower humidity levels and consume less energy at these temperatures. However, conventional dehumidifiers with compressors are generally more efficient in warmer, more humid conditions. Desiccant units typically have a lower capacity in terms of pints of moisture removed per day compared to high-capacity compressor models, but they offer more consistent performance across a wider temperature range.

Q: Are there rechargeable desiccant dehumidifiers available?

A: Yes, rechargeable desiccant dehumidifiers are available. These compact units are designed for small spaces and don’t require a power source to operate. They use desiccant materials to absorb moisture from the air until they reach saturation. Once saturated, they can be ‘recharged’ by plugging them into a power outlet, which heats the desiccant and releases the collected moisture. These are particularly useful for small, enclosed spaces like closets, gun safes, or vehicles where continuous power isn’t available or necessary.

Q: How do I know when to drain the water tank in my desiccant dehumidifier?

A: Most desiccant dehumidifiers come with a built-in water tank that collects the condensate (water removed from the air). They typically have an automatic shut-off feature and an indicator light that activates when the tank is full, signaling that it needs to be emptied. Some models also offer a continuous drain option, where you can attach a hose to the unit to direct the water to a nearby drain, eliminating the need to manually empty the tank. It’s important to regularly check and empty the tank to ensure optimal performance and prevent overflow.

Q: Can a desiccant dehumidifier be used for humidity control in a gun safe?

A: Yes, desiccant dehumidifiers are excellent for humidity control in gun safes. They are particularly well-suited for this application due to their ability to operate in small, enclosed spaces and achieve very low humidity levels. For gun safes, you can use either a small, rechargeable desiccant dehumidifier or a compact plug-in model, depending on the size of the safe and availability of power. These dehumidifiers help prevent moisture damage to firearms and other valuable items by maintaining optimal humidity levels, typically below 50%.

Q: How does temperature and humidity affect the performance of a desiccant dehumidifier?

A: Desiccant dehumidifiers are designed to perform well across a wide range of temperatures and humidity levels. Unlike compressor-based units, they maintain their efficiency even at lower temperatures, making them ideal for use in cooler environments. Their performance actually improves as the temperature drops, allowing them to continue absorbing moisture effectively even below freezing point. However, extremely high humidity levels can reduce their efficiency, as the desiccant material may become saturated more quickly. In general, desiccant dehumidifiers offer more consistent performance across varying temperature and humidity conditions compared to conventional models.

Q: What is the lifespan of the desiccant material used in these dehumidifiers?

A: The desiccant material used in dehumidifiers, typically silica gel or a similar substance, has a long lifespan when properly maintained. In most desiccant dehumidifiers, the desiccant is contained within a slowly rotating desiccant wheel that continuously cycles through absorption and regeneration phases. This design allows the desiccant to be used indefinitely without replacement under normal operating conditions. However, the overall lifespan of the dehumidifier may be limited by other components such as fans or heating elements. With proper care and maintenance, a quality desiccant dehumidifier can last for many years, often outlasting compressor-based models.