Refrigerant dehumidifiers are commonly used devices built to reduce humidity indoors by removing the excess moisture from the air. These systems use refrigeration principles, making them beneficial in many areas, such as residential buildings, commercial offices, and even factories. As with any technology, these systems have their pros and cons, which are challenging to ignore. These challenges include harmful environmental effects, high energy consumption, and low efficiency. These machines can be detrimental to the environment because of the specific operating refrigerants and high energy consumption, leading to unnecessary costs. This paper deals with the basic principles of refrigerant dehumidifier operation, looks at their positive impacts, and brings attention to the negative aspects of utilization. This should help the reader understand how the device helps manage humidity. In the end, an informed decision regarding using a refrigerant dehumidifier for any particular application will be made.

What is a refrigerant dehumidifier and how does it work?

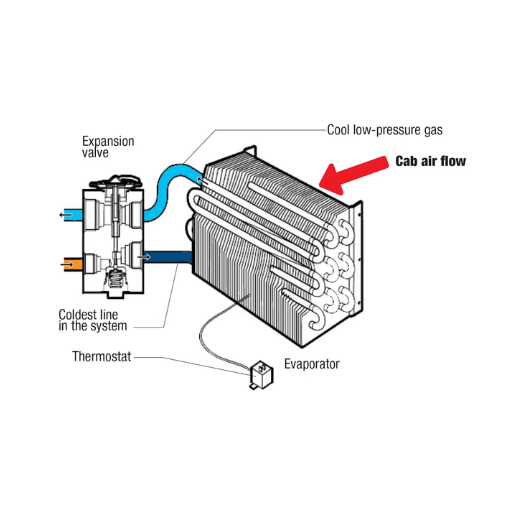

To dehumidify a place without consistent problems, a refrigerant dehumidifier offers great solutions as it is designed to remove excessive moisture from the air using a refrigeration cycle. A fan draws in humid air and passes it through a cold coil filled with refrigerant. Once the air cools down, the moisture condenses into water and is either stored in a reservoir or drained away. The air that has been dehumidified is then reheated before being released back into the atmosphere. This method is extremely effective in warm and humid conditions allowing for efficient humidity control during both commercial and industrial settings.

Basics of Refrigerant Dehumidifiers

The principles of condensation and temperature differentials guide the way a refrigerant dehumidifier functions. The evaporator coil remains colder than the dew point temperature causing water vapor in the air to condense. The condensation then is collected and stored in a tank or expelled using a drainage system. The cooled and dehumidified air passes through the condenser coil where it warms up before being released back into the area. Moreover, the refrigeration based system of the dehumidifier ensures consistent moisture removal efficiency. Therefore, these methods are beneficial in regions of high humidity and temperature.

The role of the compressor and coils in moisture removal

The compressor is an important element of the refrigerant dehumidification cycle since its function is to compress refrigerant gas increasing its temperature and getting it ready for heat exchange in the condenser coil. Condensation occurs when the incoming air is cooled to a dew point temperature. The evaporator coil is responsible for performing this task. In most cases, evaporation cooling coils are designed to operate within the 35°F to 55°F range, depending on the construction and efficiency of the dehumidifier. The condenser coil then reheats the dehumidified air to a comfortable temperature and releases it. Effective moisture removal depends on accurately adjusting refrigerant pressures, usually kept within the limits of 100 – 400 psi and determined by the refrigerant type and system. All these conditions result in a sustained and efficient moisture removal cycling process.

Evaluating the Difference Between Refrigerant and Desiccant Driers

Like many aspects of technology, both the refrigerant dehumidifiers and desiccant models have their operating functions and performance traits built in a manner that each meets a different need. In countries that have a warm and a humid environment, desiccant dehumidifiers are most effective as the temperature is above 60F. Their system employs a vapor-compression cycle allowing these models to remove moisture ranging from 20 to 70 PPD efficiently. Nonetheless, their performance decreases when used in a low temperature environment such as subzero freezing. In these temperatures, frost tends to build up on the evaporator coils and a defrost cycle is required to set the temperature back onto a normal level.

On the other side of the coin, desiccant driers work best when used in areas with a cooler temperature and low humidity levels. These work as a hygroscopic material that absorbs moisture present in the air. Similar to its counterpart, these also perform best in industrial storage conditions. Their capability of working in low temperatures that are around -4F is what allows for this particular model to work best in extreme conditions. This allows for the drier to function while lowering the relative humidity to lower than 30%. A downside to this model is that it does consume a higher amount of energy. Heating is required for the regeneration of the desiccant which causes the energy usage to spike between 500W to relative to over 1500W depending on the model being used along with the conditions set for it.

When choosing a method of dehumidification, temperature conditions, humidity requirements, energy consumption, and the specific purpose for dehumidification must be taken into account. Generally, refrigerant dehumidifiers are more energy efficient in moderate climate zones, but desiccant models outperform in more demanding low-temperature settings.

What are the benefits of using a refrigerant dehumidifier?

Dehumidificadores a base de refrigerantes brindan ventajas como efecto de gran ahorro de energia haciendo posible la eliminacion de la humedad mediante condensacion en climas de temperatura media a alta. Estas unidades son eficientes para mantener el nivel optimo de humedad al interior de los espacios y nadamas evitan la formacion de moho, daños a la estructura, y el malestar por en exceso de la humedad. Por otro lado, son de bajo costo en el mercado para el uso residencial y son de amplia disponibilidad, por lo que pueden ser usados en muchas aplicaciones.

Eliminacion de humedad en diferentes ambientes

La eliminacion de humedad con estos refrigerantes se hace ahorrando energia al emplear espirales de enfriamiento que condensadas vapor de agua en el aire. Esto, los espejos son eficaces sobre ambientes donde hay altas temperaturas acompañadas de altas cantidades de humedad. Son capaces de mantener estables Izadas calidad del aire interno, previniendo la formacion de moho y energia economizando al mismo tiempo. Al ser atres tipo de maquinaria, su confiabilidad los hace funcionar tanto en hogares, oficinas o ambientes industriales para el control de la humedad en exceso.

Energy advantages of dehumidifiers using refrigerants and their associated fan systems.

An advanced feature of these refrigerant dehumidifiers is their energy savings in the use of high quality humidity sensors, which allows for precise monitoring and regulation of operation depending on the conditions. Thus, the unit works only when it is required, cutting down energy use. Moreover, a number of these models are equipped with efficient compressors and eco-friendly refrigerants to improve performance and reduce impact to the environment. Some models even provide variable fan speeds, energy-saving modes, and other features that enhance functionality without effectiveness, thus further reducing power output. These factors make refrigerant dehumidifiers an effective energy saving solution for the management of indoor air quality.

Low operational noise issues for users at home or in bedrooms.

Modern refrigerant dehumidifiers are designed with cutting-edge low operational noise technologies, making them adaptable for home or bedroom use. Many models now have operational sound levels in the range of 30 to 40 decibels, which means they can function with the minimum disruption for sleeping or relaxing. As a result, quiet fan modes, efficient motors, and low operating sound create comfortable and calm indoor environments while managing humidity levels.

How do I choose the right refrigerant dehumidifier for my needs?

When selecting a refrigerant dehumidifier, it is essential to consider certain aspects, such as space size, desired humidity, and other features that are unique to the environment. The first task in this instance is to define the dehumidifier’s capacity, which is set in pints per day, and this, in turn, should strive to ideally match the room’s square footage and the moisture content. In case of larger or very damp spaces, a unit with higher capacity should be selected as this will improve performance. Energy efficiency is another important aspect; search for energy star-rated models that consume less energy. Also, hygrometers, programmable timers, and ease of maintenance such as removable and washable filters should be considered. Noise levels are another area of concern, so always select low-decibel models for bedrooms and quiet spaces. With a comprehensive assessment of these features, effective humidity management can be achieved effortlessly.

Understanding pint capacity and room size

While assessing the pint capacity and room size, pay attention to the ratio of the dehumidifier’s capacity and the environmental conditions. Pint capacity measures the level of moisture that a dehumidifier can eliminate from its surroundings daily. To give an example, a 30-pint can comfortably serve areas less than 1500 sq. ft. that are moderately damp. But suppose the room is highly humid, such as a basement. In that case, the unit can adequately service only about 500 to 1000 sq. ft. Larger units are on-demand, like the 50 and 70-pint units that are even required for larger areas and higher humidity.

Considerations such as temperature and humidity of the room must be factored as these are detrimental to the workability of the dehumidifier, especially refrigerant units that work effectively in warm settings. Many models include a cart showing the recommended uses for different levels of dampness, which can be summarized as follows:

- Moderately Damp(benefital range of humidification): 50-60% RH 1.5 pint per 100 square foot.

- Very Damp(poor conditions): 60-70% RH 2 – 2.5 pints per 100 sq ft

- Wet Beam (too high humidity area): greater than 70% RH 3-4 pints every 100 square foot

Take into account different room configurations, like irregular shapes, tall walls, or any extra sources of humidity, which can include closed-off rooms or open areas next to the room. Doing so will help you accurately gauge these variables. Considering the dehumidifier’s capacity in this setting ensures active humidity management without extra energy costs or unit underperformance.

Taking into account portable dehumidifiers versus central whole house dehumidifiers

The choice between a portable dehumidifier or a central one depend primarily on the user’s needs and how much space they want to treat. Portable dehumidifiers are designed for a specific use, meaning they are smaller in size as they are affected by 20 to 70-pint ranges per day. For example, these ranges allow around 4000 to 4500 square feet to be treated depending on how much humidity is in the room and it’s condition. Portable dehumidifiers are cost-effective, which enables them to serve small to medium spaces with specific uses. However, they also require manual maintenance and emptying of the water reservoir.

As opposed to individual room dehumidifiers, which are portable and manually operated, integrated dehumidifiers are designed to be used with the HVAC system of the building and can remove moisture from entire structures. These units are best suited for large households of over 4 people or regions with high humidity throughout the year since they can extract over 90 pints of moisture per day. Some models also use automated climate control, noise reduction, and ducted airflow distribution, enhancing their efficiency. While the electricity costs associated with these systems is much lower, their initial installation cost is quite high. After installation, however, very little supervision is needed.

The primary consideration with these systems is the expense, which comes hand in hand with the scale of control required, as well as the type of environment they are going to be used in, whether it is occupied or centralized.

Features to look for in a refrigerant dehumidifier

- Capacity: The pint capacity indicates the daily volume of moisture removed. Ensure to choose the appropriate model for the intended area to increase the pint capacity, such as larger high-humidity quarters.

- Energy Efficiency: Dehumidifiers with Energy Star certification or high energy ratings would be best since they are the most inexpensive to operate and the most environmentally friendly.

- Adjustable Humidity Control: Setting a desired value for the relative humidity (RH) enables the device to maintain suitable indoor air conditions as per the varied needs.

- Auto-Defrost Feature: This feature allows the unit to factor in lower temperatures to avoid coil freeze, consequently enhancing the unit’s longevity while maximizing unit performance.

- Durability and Build Quality: Robust coils and corrosion-resistant components built into the units using high-quality materials enhance performance and durability.

- Drainage Options: Automatic water removal such as an internal pump or capability for continuous drainage reduces manual maintenance work.

- Noise Levels: Low decibel operation is paramount for bedrooms and even office settings where noise could be problematic.

- Filter Maintenance: Ensure the unit comes with proper filters for easy cleaning, which enhances air quality and increases efficiency.

- User Interface and Controls: Easy-to-use digital interfaces or other smart controls, such as mobile app access, keep the user comfortable.

- Portability and Design: Users who require cross-space movement would benefit from compact designs with built-in handles and caster wheels.

What are the drawbacks of refrigerant dehumidifiers?

Although performant in different spaces, refrigerant-based dehumidifiers have some significant limitations. For instance, they are typically less effective in colder temperatures because the refrigerant coils are less efficient in condensing moisture from cool air. Because of this restriction, they are not fit for spaces that are not heated- for example, garages or basements in cold regions. In addition, the design of these devices can be bulkier and of bulkier and heavier materials than the desiccant variety, thus limiting portability. Maintenance activities such as cleaning coils, replacing filters, or cleaning the filters can also be stressful. In addition, there is some concern over the environment with refrigerants that can create harmful emissions if not disposed of properly. Additionally, these units might use more energy with larger or more powerful models. These and other issues in refrigerant-based dehumidifier units should be balanced by the possible benefits.

Issues with performances in low temperature conditions:

Beneath thermal conditions, refrigerant dehumidifiers performance is restricted by the pressure characteristics of refrigerants. In temperatures around 18 degrees Celsius or 65 degrees Fahrenheit, warm air has a higher condensing potential but is still insufficient for effective condensation. In addition, the coils may freeze over and become a defrosting hassle that impedes cold air ventilation. Redundant processes like these increase energy consumption and, as a result, reduce efficiency, limiting refrigerant dehumidifier applications to heated areas like basements, crawl spaces, and outdoor cupboards. Economical energy use may be achieved through the adoption of desiccant dehumidifiers.

The need for constant servicing and sanitation

An air dehumidifier requires regular servicing and cleaning to reach its highest degree of efficacy and usable life. I work hard to keep the air filter clean, since a clogged filter reduces airflow and efficiency. It is also essential to clean and disinfect the water collection reservoir occasionally to limit the possibility of mold and bacteria colonization. Furthermore, I pay attention to the coils and fins of the unit and clean off any dust or debris that can hinder heat exchange. If such models have a defrost mechanism, I check its function to ensure proper operation during lower ambient temperatures. These simple actions allow the device to work better and reduce the chance of breakdowns.

Possible refrigerant leakages and their implication on the environment

Dehumidifiers face high risks of refrigerant leakage, which can potentially have dire impacts on the environment and operational processes. A large number of refrigerants such as hydrofluorocarbons (HFCs) create greenhouse gases that can inflict high amounts of damage to the environment on a global scale. As for the R-410A and R-134a refrigerants used in many dehumidifiers, their Greenhouse warming potential (GWP) is at a staggering 2088 and 1430, respectively, which increases the need for effective leak prevention strategies. Insufficient refrigerants in a device lead to lowered efficiency, impacting the cooling coil’s capability to condense moisture effectively. Additionally, specialized electronic detectors are needed for leak detection, which enables repairs such as resealing connections or replacing damaged components. Lastly, preventing leakages require a constant check on the refrigerant lines and joints. The responsible disposal of refrigerants also highlights the vital need for professional maintenance.

How do refrigerant dehumidifiers compare to desiccant models?

A refrigerant and a desiccant dehumidifier work differently; each is best suited for a specific purpose. A refrigerant dehumidifier condenses moisture in the cooled air and is, therefore, most effective in hot and humid conditions. However, their efficacy is considerably reduced in cold environments because coils can freeze within the unit. In contrast, desiccant dehumidifiers can be relied upon in low temperatures because they remove moisture from the air through adsorbents instead. Though desiccant units are energy-inefficient and bulky, they are also compact, quiet, and specialized. This makes them ideal for residential homes concerned with noise pollution. Choosing between the two depends heavily on the energy efficiency goals and the specific surrounding conditions.

Change in Types of Methods of Moisture Removal Including Efficiencies

The efficiencies of refrigeration and desiccant dehumidifiers differ tremendously because of the differences in their principles of operation. Refrigeration dehumidifiers work best in hot, humid environments and tend to remove moisture ranging between 20 to 50 pints per day on average and sometimes even more depending on the unit’s capacity and other environmental conditions. However, their performance drops below 60 degrees Fahrenheit because condensation becomes less efficient and frost forms on the coils. Furthermore, unlike the refrigerant types, desiccant dehumidifiers can keep a constant moisture removal rate even in cold environments where the former fails to do so. They work best at temperatures lower than 41 degrees Fahrenheit because the desiccant material captures moisture irrespective of the situation. So, although the desiccant units tend to use more energy than the refrigerant units, they are very reliable in low-temperature situations and less affected by sharp air temperature or humidity changes. Depending on the environment and the moisture removal rate required, one has to choose the unit’s design carefully.

Energy consumption comparison

There exists a stark divide between the energy consumption of refrigerant models, which typically consume around 300-700 watts, and desiccant ones, which usually consume around 600-1200 watts. In standard residential units, battery consumption is markedly lower than its counterpart, leading to more cost efficient options when the temperature is warm and the air is humid. However, the performance of desiccant dehumidifiers outshines their competitors in temperatures below 41°F, being able to operate in environments where refrigerant models are inefficient. In turn, the correct variant can be chosen by analysis of energy use, target environment, and estimated usage. This ensures the optimally efficient option is selected for every unique application.

Suitability for different climates and applications

Desiccant dehumidifiers work best for colder climates and environments and for applications that require maintaining performance in lower temperatures. This results from their ability to operate efficiently in environments below 41°F, allowing them to be used in unheated basements, certain storage units, or manufacturing facilities that require a specific humidity level. Their ability to work in low ambient temperatures is made possible due to the runaway of desiccant material, which functions independent of outside conditions.

Refrigerant dehumidifiers, in contrast, are best suited for hot, humid environments, performing best when temperatures are above 15°C. They are even more effective in residential or commercial areas like living rooms, offices, and retail spaces, which use condensation for moisture removal. However, their effectiveness drops drastically in colder environments because of coil freezing, which obstructs the condensation cycle.

As one contemplates application-oriented requirements, it is necessary to look into operating range, moisture removal rate (in pints per day, maximum), and energy efficiency ratio. Desiccant units may have lower maximum EER at a higher temperature range than refrigerant units, but their performance equilibrium at low temperatures gives them an edge for special-purpose usage. Where temperature is stable and moderate, refrigerant units are mostly preferred because of their higher EER at warm conditions.

What is a Low Grain Refrigerant (LGR) dehumidifier?

Contrary to conventional refrigerant dehumidifiers, LGR units incorporate a specialized pre-cooling technology that reduces the temperature of the incoming air before it contacting the evaporator coils, enhancing the coils ability to extract water vapor from teh air. For these reasons, LGR dehumidifiers have proven invaluable for water damage restoration, construction drying, and controlled environmental chambers where lower Specific Humidity (SH) levels are required. It is these scenarios that distinguish LGR dehumidifiers from conventional refrigerants. Instead, they are extremely effective for high moisture locations.

How LGR dehumidifiers work

Moisture extraction is a critical process for LGR dehumidifiers, and modern techniques in refrigeration and airflow have aided in their development. The main concept involves combining conventional and evaporative cooling whereby pre-cooled air is passed over the evaporator coil to maximize water vapour condensation. These systems include sophisticated heat exchangers and propellers to relieve reverse cycle pressure so as not to operate efficiently most of the time. In addition, these units are entirely sealed to not only improve the performance and SH levels, but to eliminate air leakage. This advanced technology drastically increases the range of humidity levels operable by the LGR dehumidifiers compared to conventional models.

Advantages of LGR dehumidifiers for business use

Owing to their enhanced moisture extraction efficiency, LGR dehumidifiers offer great benefits in commercial premises. They guarantee the fastest drying rates, essential for the water damage restoration industry and construction. By extracting moisture efficiently, the chances of mold formation and damage to the establishment’s infrastructure is significantly reduced- thus, protecting the property and improving air quality. Moreover, LGR units have been proven to use lower energy when operating than standard models, thus, providing economical and eco friendly operation. Their rugged construction and ability to withstand harsh environmental conditions enable them to deliver much-needed reliability for large-scale moisture control operations.

When to select LGR dehumidifier as opposed to the more common types

In instances when there is an increased possibility of moisture in the atmosphere or severe water damage has occurred, Low Grain Refrigerant (LGR) dehumidifiers would be more efficient compared to standard models. The standard model of LGR dehumidifiers make use of advanced cooling components, and also includes an additional heat exchanger to decrease further the temperature of air that is being drawn in before the moisture extraction process. The design allows for lower specific humidity levels and dew points to be set. This makes the dehumidifiers perfect for restoring structures that have been soaked with water, or any other facility where precision humidity levels are required.

In particular, LGR units are designed to work under extreme operating conditions and are able to function even when relative humidity is below 40%. They also tend to perform better at temperatures of 90°F and lower than standard dehumidifiers. Additionally, average ‘pint standard models’ may have a removal rate of between 50-70 pints per day, while high capacity LGR dehumidifiers have an extraction rate of more than 130 pints per day (AHAM-rated at 80°F and 60% RH). This ensures large-scale applications have faster drying cycles and improves efficiency. Selecting an LGR type dehumidifier is necessary when water intrusion moderation demands higher drying expectations.

Reference sources

Frequently Asked Questions (FAQs)

Q: What is a refrigerant dehumidifier and how does it work?

A: A refrigerant dehumidifier, also known as a compressor dehumidifier, works by drawing moist air over a cold coil. This causes the moisture to condense and collect in a water tank or drain through a hose. The dry air is then reheated and released back into the room. These dehumidifiers are efficient in warmer temperatures and are commonly used in homes and basements.

Q: How does a refrigerant dehumidifier compare to a desiccant dehumidifier?

A: Refrigerant dehumidifiers are generally more energy-efficient and work better in warmer temperatures, while desiccant dehumidifiers are better suited for colder environments. Refrigerant models are typically less expensive and more common for home use, whereas desiccant units are often used in commercial settings or very low-temperature applications.

Q: What are the benefits of using a refrigerant dehumidifier for home humidity control?

A: Refrigerant dehumidifiers are effective at reducing humidity in homes, helping to prevent mold growth, musty odors, and damage to furniture and belongings. They’re particularly useful in basements, bedrooms, and other areas prone to moisture. Many models are Energy Star certified, making them energy-efficient choices for dehumidifiers for home use.

Q: Are there any drawbacks to using a refrigerant dehumidifier?

A: While refrigerant dehumidifiers are efficient, they can be less effective in colder temperatures and may require a defrost cycle. They also contain refrigerants, which can be harmful to the environment if not properly disposed of. Additionally, the compressor can make these units noisier than desiccant models, though many quiet dehumidifier options are available.

Q: What size refrigerant dehumidifier do I need for my basement?

A: The size of dehumidifier you need depends on the area and humidity level of your basement. For most basements, a 50-70 pint dehumidifier is suitable. A 70 pint dehumidifier is often recommended for larger or very damp basements. Consider a dehumidifier for basement with drain to avoid having to empty the water tank frequently.

Q: How do I maintain my refrigerant dehumidifier?

A: To maintain your refrigerant dehumidifier, regularly clean the air filter, empty the water tank (if not using a drain hose), and clean the coils. Ensure proper airflow around the unit and check for ice buildup on the coils. If you’re using a dehumidifier with drain hose, make sure the hose is clear and properly positioned. For specific maintenance instructions, refer to your user manual or contact us for assistance.

Q: Can I use a refrigerant dehumidifier in my garage?

A: Yes, you can use a refrigerant dehumidifier in your garage, but keep in mind that these units work best in temperatures above 60°F (15°C). If your garage gets colder than this, you might need to consider a desiccant model. Also, ensure proper ventilation and drainage options, as garages can produce a lot of moisture. A dehumidifier with a drain hose option can be particularly useful in this setting.

Q: Are portable refrigerant dehumidifiers available for smaller spaces?

A: Yes, portable refrigerant dehumidifiers are available in various sizes, including smaller units suitable for bedrooms or other compact spaces. These portable dehumidifiers are easy to move and often come with features like automatic shut-off and humidity control. When choosing a dehumidifier for a bedroom, look for quiet models to ensure a peaceful sleeping environment.