The regulation of humidity in big industrial setups is a vital aspect of keeping production running smoothly, extending the life of machines, and maintaining the quality of raw and finished goods. Corrosion, mold, and poor air quality are some of the problems that, among others, can be caused by too much humidity; the proper functioning of equipment and the health and safety of workers are at risk. This article tells the story of industrial large dehumidifiers as the heroes that save the day when the moisture level goes beyond limits. Understanding their working and usage, in the sectors that gain the most, we will conduct a thorough investigation into the necessity of these systems for moisture management. Join us in revealing how industrial dehumidification technology is being deployed to alter environmental management, lift productivity, and protect the assets of the company.

Understanding Large Industrial Dehumidifiers

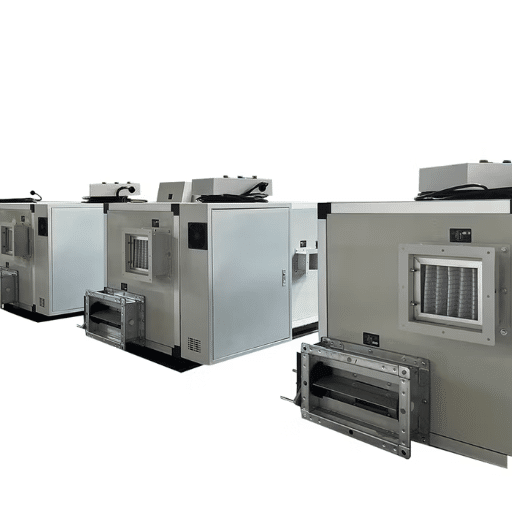

Large industrial dehumidifiers are large systems specifically built for controlling and decreasing the humidity of big areas. These systems draw in the humid air, water vapour is removed through either condensation or desiccant materials, and finally, the dry air is blown back into the surrounding area. They are a must in the manufacturing, storage, pharmaceutical, and food processing industries, where controlling the humidity is extremely important. Their main aim is to eliminate problems caused by moisture, especially mold, decay, rust, and unsafe working conditions. Besides being efficient, industrial dehumidifiers are also dependable, and thus, they have become an important component in the maintenance of the best environmental conditions in large-scale operations.

What is a Large Industrial Dehumidifier?

A heavy industrial dehumidifier is a powerful mechanical apparatus that is engineered to manage and eliminate moisture in vast areas. Such devices work by taking away the moisture that is in excess from the air through either the refrigeration or desiccant methods. The refrigeration type cools down the air to the point where water vapor forms and is then removed, and the desiccant type uses chemical agents that absorb moisture even in cold air. They have been developed for massive units, which is why they are fit to be used in places like warehouses, factories, data centers, and other places where the humidity levels need to be strictly controlled to prevent any damage to the products, equipment, or processes. The constructions of these devices are strong, and the controls advanced, thus ensuring their operation is reliable and energy efficient even under tough industrial conditions.

How Dehumidification Works

Dehumidifying is the process of extracting moisture from the air to ensure that the humidity level is ideal in a certain place. This process normally consists of two main systems: refrigeration-based and desiccant-based. Refrigeration-based dehumidifiers work by using coils cooled by a refrigerant to draw air in and thus causing moisture to condense into water, which is either collected or drained off. Desiccant dehumidifiers, on the other hand, use hygroscopic materials like silica gel to remove moisture directly from the air, thus making them useful in low-temperature or low-humidity settings.

The whole process starts when an intake fan draws air into the dehumidifier. In the case of refrigeration types, the air is led over cold evaporator coils where water vapor condenses, and then it is reheated again by the condenser coils before being released back into the room. In the case of desiccant types, the air is brought to the desiccant material where the water molecules are trapped, while the heating process is carried out to regenerate the desiccant for continuous operation. By applying a controlled method for humidity adjustment, a range of problems, such as mold growth, corrosion, and product quality degradation, are avoided across residential, commercial, and industrial use.

Types of Dehumidifier Systems

The operational mechanisms and the use cases of dehumidifier systems can be further divided into three types:

Refrigerant (Compressor-Based) Dehumidifiers

Refrigerant dehumidifiers are the most popular among all, and they operate by the simple process where air is pulled over the cold evaporator coils, and that water vapor gets changed back to the liquid state. The water that is formed is collected, the air is heated again, and then it is let out. These types of dehumidifiers are very efficient in warm and humid places, which means they are mostly used in residential or commercial areas where the indoor temperatures are usually above 65°F (18°C).

Desiccant Dehumidifiers

Desiccant systems trap the water particles with the help of hygroscopic materials, silica gel being the most common one. In these types of dehumidifiers, a regeneration cycle is done where the desiccant is heated, and the moisture is released. These types of dehumidifiers work really well in cooler climates or places with low humidity, as they do not need the temperature difference for their efficiency. They are often found in industries or warehouses where humidity needs to be controlled very accurately.

Thermoelectric (Peltier) Dehumidifiers

Working on the Peltier effect, the thermoelectric dehumidifiers grab the moist air, then pass it through a solid-state heat pump, creating a temperature difference, and the water gets condensed on the cold side. These types of dehumidifiers are small, light in weight, and consume less energy, but at the same time, they have a lower moisture removal capacity than compressor-based units. They are good to use in limited areas like bedrooms, closets, and bathrooms where only a small amount of moisture has to be removed.

With each system possessing specific strengths according to the nature of the environment and the demands of the application, dehumidification technology proves to have great flexibility.

Benefits of Using Heavy-Duty Dehumidifiers

Improved Air Quality

The use of heavy-duty dehumidifiers not only cuts down on the amount of moisture in the air but also effectively prevents mold and mildew from growing. This eventually results in air that is cleaner and healthier, plus considerably fewer allergens that are capable of causing respiratory diseases.

Protection of Materials and Equipment

These dehumidifiers keep humidity at the right levels, which in turn prohibits the activities of rust, corrosion, and warpage of different materials, ensuring the safety of sensitive equipment, machinery, and even the stores of goods.

Energy-Efficient Performance

Heavy-duty dehumidifiers, which are designed for large-scale or continuous working, usually come with energy-efficient systems; therefore, the high initial purchase cost is compensated during extensive usage without incurring too much in power bills.

Versatility and Durability

Heavy-duty dehumidifiers that can withstand the toughest conditions are the best for a variety of places, such as industrial warehouses and flood restoration sites, thus ensuring their reliable and consistent performance throughout.

Reduced Maintenance Costs

Humidity-related damage that gets avoided through constant dehumidification leads to a long-term decrease in repair and maintenance costs for structures, equipment, and inventory.

Energy-Efficient Moisture Control

Dehumidifiers that use less energy are able to efficiently control moisture and, at the same time, consume less energy thanks to advanced technologies like variable-speed compressors and smart humidity sensors. The innovations enable the systems to operate in a manner such that the target humidity level is reached using the least amount of energy. The energy-efficient dehumidifiers that meet Energy Star standards not only mitigate carbon emissions but also provide a substantial amount of money saved over the years. Besides, the use of energy-efficient methods for moisture control has the effect of preventing mold growth, rust, and material deterioration, which is a way of preserving the assets for a longer period and improving the quality of indoor air with reduced operational costs. Their use in both residential and industrial settings is proof of their versatility to different requirements without giving up on performance or efficiency.

Preventing Water Damage in Industrial Spaces

The protection of industrial spaces from water damage necessitates a multi-aspect strategy that consists of proactive maintenance, upgrading the infrastructure, and environmental assessment. Some of the major measures are the installation of proper drainage systems that would lead excess water away from the building and regular checks of plumbing and roofing for leaks or vulnerabilities. Applying water-resistant materials and sealing off places that are more likely to receive water can protect buildings and equipment of utmost importance.

High-tech detection of moisture, like sensors and alarms, can warn of leaks early, and that will allow for timely actions. Alongside, humidifiers and ventilation systems are seen as the major elements in controlling the humidity inside the building, and those are especially useful in places where condensation is a threat. Training of workers in identifying and preventing water-related hazards will significantly cut the risk of damage. When these measures are put together, manufacturing plants will realize not only risk reduction of water damage but also, to a great extent, non-operational periods, expensive repairs, and loss of asset value.

Improving Air Quality and Comfort

The improvement of air quality and the provision of comfort to the occupants require nothing less than a multi-pronged strategy that will bring together cutting-edge technologies and the application of best practices. High-efficiency particulate air (HEPA) filters as well as ventilation systems have become indispensable in the process of reducing health hazards caused by the presence of airborne contaminants, namely, dust, pollen, and microorganisms. Air purifiers with activated carbon filters can be employed to remove VOCs and odors, which is another step towards enhancing indoor air quality. The necessary maintenance, which covers regular cleaning and filter replacement, guarantees that the system operates at its best.

Furthermore, the control of temperature and humidity is a very important factor in the overall comfort of the occupants. HVAC systems fitted with smart thermostats and humidifiers provide the means for close monitoring of the environmental conditions and thus control them to the exact requirements of the various spaces and activities. The indoor air quality monitoring could be done by using the IoT-connected sensors, and this will allow for real-time adjustments to lower the pollutant levels and keep the comfort consistent. By taking advantage of these strategies, the facilities will be able to not only provide their inhabitants with a healthier and more pleasant environment but also, at the same time, become the champions of energy efficiency and the well-being of the people working there.

Applications of Large Industrial Dehumidifiers

Effective humidity management by large industrial dehumidifiers has many applications to be considered as indirect and direct causative factors of success in different areas. They are used in manufacturing plants, for example, to eliminate the possibility of raw material and finished product going bad because of moisture, and also to ensure that the whole production process runs smoothly. Likewise, they are of great importance in warehouses where the formation of mold and mildew, which can lead to loss of product quality and even complete rejection, is reduced. It is also common to find these systems in water damage restoration projects to facilitate the process of drying and, hence, lessening the extent of structural damage. Such appliances, however, are not limited to water treatment facilities only but are also increasingly being adopted in climate-sensitive industries, such as pharmaceuticals and food production, where maintaining the highest quality and meeting regulatory requirements depend entirely on precise humidity control.

Dehumidification in Warehouses

Dehumidification in warehouses is a critical step in assuring quality storage conditions and, consequently, safeguarding the stored goods against moisture-related damage. Excessive humidity is a fact of life in some places and a major cause of mold, corrosion, and flaking of materials among the sensitive ones, not speaking of the financial losses that come along. By using industrial dehumidifiers, warehouse staff can oversee the climate so that even the most delicate types of products, like electronics, textiles, and food, do not spoil.

The dehumidification systems have a big impact on the safety of the workers, given that one of the major causes of accidents in warehouses is condensation, creating slippery areas and supporting the growth of bacteria. The latest systems incorporate the cutting-edge technology of desiccant or refrigerant dehumidification, which could accommodate customers’ exact requirements through perfect humidity control. Besides, the practice of humidity control not only helps in saving energy but also enhances the durability of the building systems, thus being a major factor in the overall efficiency of the warehouse operations.

Dehumidifiers for Special Needs

Dehumidifiers made for special needs have specific features useful in places where humidity control has to be done very precisely or in very high and strict settings, like hospitals, laboratories, cleanrooms, and industrial plants. These units usually come with advanced filtration, HEPA filters, or even antimicrobial materials to keep the air clean while being able to manage the moisture level. The dehumidifiers made for storage, for example, in museums and archival facilities, protect the items that are sensitive, such as documents, fabrics, and art, from degradation due to high humidity. There are also portable or compact units available for areas with size restrictions that provide flexibility without losing efficiency. Innovations in smart control systems have made it possible to continuously monitor and automate humidity levels to be the most precise and best suited for the critical applications.

Choosing the Right Dehumidifier for Your Needs

There are three major considerations when deciding on the right dehumidifier: the size of the area, the humidity level, and the intended use. A powerful dehumidifier is suggested for places that are very large and have a lot of moisture, as this will make the process of dehumidification much more effective. Smaller areas, like bedrooms or bathrooms, should get compact dehumidifiers that are very convenient and yet not as powerful as the larger models. Besides, think about other features such as humidity control, energy-saving ratings, and noise levels that best fit your requirements. If the area has very sensitive materials, then getting units with very good humidity controls is necessary to avoid the materials being damaged. However, you should always check the specifications of the product to ensure that the dehumidifier’s capacity is appropriate for the size of your space.

Factors to Consider When Selecting a Dehumidifier

| Factor | Description |

|---|---|

| Room Size and Coverage Area | Choosing a dehumidifier that can handle the size of the room you want to dry out is very important. Calculate the area in square feet of the place, and check the suggested coverage area for the unit. If the area is larger and has a lot of moisture, using a dehumidifier of higher capacity might be a good idea to keep the moisture removal at its best level. |

| Humidity Levels | To set the right dehumidifier size, reducing the relative humidity of the space is necessary. Units with higher pint-per-day (PPD) capacity are usually required to efficiently keep moisture in basements or crawl spaces under control. |

| Energy Efficiency | When looking for a dehumidifier, pick models that come with energy-saving certifications like the ENERGY STAR-rated dehumidifiers. Though these units are less power-consuming, their performance remains the same, thereby lowering the running costs over the years. |

| Drainage Options | Ask yourself if the dehumidifier has a non-stop drainage feature or a built-in pump for efficient removal of water to save you time and labor. When it comes to manual models, make sure the tank for collecting water is easy to reach as well as clean. |

| Noise Levels | Noise level is a very important aspect, especially for places where people live or sleep. If quiet operation is foremost in your considerations, then go for a unit with a low decibel rating. |

| Controls and Features | Advanced settings like adjustable humidistats, timers, auto-defrost, and smart connectivity for remote monitoring are often found in modern dehumidifiers. Such features will make the product more user-friendly and precise. |

| Durability and Maintenance | Check the unit’s construction quality and look for customer feedback to get an idea of its durability. Maintenance costs can be less if the filters are washable and the parts are easy to access. |

Taking these factors into account, you are able to pick up a dehumidifier that not only fits your needs but also operates according to your requirements.

Comparing Refrigerant vs. Desiccant Models

When it comes to choosing the right dehumidifier between the refrigerant and desiccant types, it’s a must to evaluate the very nature of their operation, performance, and even the locations where they can be used the most. Refrigerant dehumidifiers perform the task of moisture removal through condensation, and they need a compressor and cooling coils to do it. The units deliver their best performance when the outside temperature is hot, and the humidity is high—the efficient operation range is between 60°F and 95°F. They produce high moisture extraction rates and are the least power-consuming appliances in those conditions. On the downside, if the temperature drops below 59°F, the ability to condense moisture gets very poor, and hence the overall output declines significantly.

Desiccant dehumidifiers consider the old-fashioned way of soaking up moisture through a specialized material (a desiccant) and then heating it up to do the regenerating (drying) process of the desiccant. These units are highly effective in areas with very low humidity and cold temperatures, and thus, they are most suitable for unheated places such as basements, garages, or industrial areas. Usually, they are quiet and light-weight but due to constant heating and cooling to regenerate the desiccant, they consume more electricity.

It all depends on the environment where they are going to be used. In the case of using them in the house, refrigerant ones are most likely chosen due to their lower electricity bill in a temperate climate. On the other hand, for cold or special applications where moisture control is critical, desiccants are preferred. Plan well-intended usage, energy considerations, and then make the right choice.

Assessing Capacity and Coverage Area

In the process of selecting a dehumidifier suitable for a particular area, one of the most important factors is to consider the capacity and moisture control of the area very precisely. The capacity of a dehumidifier is an industry standard measured in the number of pints of moisture it can remove from the air in a day (Pint/Day) and is directly dependent on the size of the space and the humidity level. Dehumidifiers rated for 20-30 Pint/Day are the right choice for small spaces with low humidity, while large areas with high humidity might need dehumidifiers rated for over 50 Pint/Day.

Moreover, the maximum area that a unit can effectively deal with is indicated by the coverage area specifications, which are often given in square feet. In order to get the best performance out of the dehumidifier, the capacity of the dehumidifier must be matched with the size of the room and the existing moisture levels. It is better to choose a dehumidifier that is slightly above the projected needs to accommodate for changes in the environment or maximum humidity levels.

Maintenance and Care for Dehumidifier Systems

Offering the right kind of care and maintenance to your dehumidifier not only guarantees its effective operation but also prolongs its life. The following major steps should be taken:

- Regular Filter Cleaning: The air filter needs to be removed and cleaned every two weeks or according to the instructions in the user manual. Because of the clogged filter, the airflow and efficiency are reduced.

- Empty the Water Tank: To stop mold or bacteria from growing, the water reservoir should be emptied and cleaned frequently. For cleaning, use mild soap and water.

- Inspect the Coils: Looking at the evaporator and condenser coils for dust or debris buildup is necessary. Clean them carefully to keep the performance up.

- Check the Drainage System: If the dehumidifier you have offers continuous drainage, then make sure that the hose is tightly attached and there is no blockage.

- Positioning: For allowing proper airflow, the unit should be placed on a flat surface with at least 12 inches of space left on all sides.

- Seasonal Storage: When the unit is not being used, the tank should be emptied, the unit cleaned, and the unit stored in a dry place to avoid damage.

Following these steps will ensure your dehumidifier is working well and can avoid unnecessary repairs. Manufacturer’s guidelines should always be consulted for specific care instructions regarding your model.

Regular Maintenance Tips

- Clean the Filter: Make it a habit to take the air filter out for cleaning and cleaning every two to three weeks so that the airflow remains at its best and dust doesn’t settle in the machine. Give the filter a rinse with lukewarm water and let it properly dry before putting it back in place.

- Inspect the Coils: Every now and then, look at the evaporator and condenser coils and see if there is any dirt or frost on them. Be very gentle when you clean the coils with your soft brush or vacuum so that their efficiency is not reduced nor the airflow blocked.

- Empty and Clean the Reservoir: If you are using a hose, consistently empty the water tank or make sure the drainage system is working properly. Clean the tank with mild soap and water to stop the bacteria and mold from growing.

- Check the Humidistat: Make sure the humidistat is set at a level that is suitable for the indoor humidity you want (this is usually 30% to 50%). Also, make sure that it is working properly so that the system operates efficiently.

- Examine Electrical Components: Regularly check the power cord and plug for signs of wear and tear. If you find any damaged parts, replace them right away to eliminate the possibility of electrical hazards.

By following these simple maintenance practices, you will be able to extend the life of your dehumidifier, get the most efficient performance, and also significantly reduce the occurrence of technical problems. Do not forget to check the user manual of your dehumidifier for any model-specific guidance.

Troubleshooting Common Issues

When troubleshooting common dehumidifier issues, I usually start by identifying the symptoms. If the dehumidifier is not collecting water, I first check whether the humidity level in the room is above the set target and also if the filter is possibly clogged. I check the fan or compressor for obstructions or wear when there are faint sounds or unusual noises. If the unit does not turn on, I check the power supply and examine the electrical parts. Working on these issues one after another generally helps to fix most of the problems in an effective way.

When to Call a Professional for Repairs

Basic troubleshooting can help with a lot of dehumidifier problems, but there are still occasions when the help of a professional is needed. Leaking refrigerant from the dehumidifier is a clear sign that the sealed system has a malfunction, and this requires specialized tools and skills to fix. Also, persistent compressor problems like failure to start or strange noises from inside, despite cleaning and inspection, should also be checked by a professional. Electrical issues like blown fuses, tripped breakers, or wiring damage should be left to the experts because of the hazards involved. Furthermore, if the appliance keeps failing to collect water even though the humidity levels are right, the filter is clean, and there are no problems at the condenser or evaporator, it is time to have a professional check and repair the internal component. The hiring of a qualified technician guarantees that the issue will be properly diagnosed and repaired without further damage being done.

Reference Sources

U.S. Department of Energy (DOE)

This document outlines proposed energy conservation standards for dehumidifiers, ensuring compliance with regulatory requirements for industrial applications.

“A Review of Solar Desalination Methods for Remote Areas”

The HDH systems discussed can be adapted for industrial dehumidification purposes.

The findings apply to the design and optimization of large industrial dehumidifiers.

Frequently Asked Questions (FAQs)

Commercial dehumidifier: What exactly is a large industrial dehumidifier, and what are its main differences compared to a commercial dehumidifier?

A large industrial dehumidifier is a powerful and heavy-duty appliance with a large volume of airflow and moisture-pumping capacity. For instance, the machine can be used in large areas like warehouses, production lines, water sports centers, and plant nurseries. On the other hand, commercial dehumidifiers are of smaller sizes and designed only for commercial environments like retail or small offices. However, these industrial units have more substantial CFM capacity, more robust condensate handling, more durable cabinets like steel, and a wider range of dehumidification enhancement system options. The main differences between industrial and commercial models are size, dehumidification needs, and product life when used continuously.

Desiccant dehumidifiers: In what situations are desiccant dehumidifiers more advantageous than refrigerant ones?

Desiccant dehumidifiers are designed for cold environments and processes where low relative humidity (RH) is required. They excel in low-temperature or low-RH industrial applications such as food processing, pharmaceutical clean rooms, or certain water damage restoration projects. Refrigerant-style commercial dehumidifiers are typically more efficient at moderate temperatures and indoor pools, but desiccant units can help where cold air or extremely low RH is needed.

Water damage restoration: Is it possible to use a large industrial dehumidifier in the process of water damage restoration?

Yes, of course. Dehumidifiers can be very effective in the process of water damage restoration as they can pull excess moisture out of the air and building materials. High-performance room dehumidifiers and industrial units designed for water mitigation help control humidity, accelerate drying, and reduce the risk of mold. Facility managers should select units with appropriate cubic feet capacity and condensate management for the affected square footage and ceiling height.

Room dehumidifiers: Can you tell me the difference between sizing a large industrial dehumidifier for my space and sizing room dehumidifiers?

Sizing depends on the square footage, ceiling height, initial RH, and the level of moisture generation (for example, pools produce more humid air). Room dehumidifiers are sized for residential or small commercial rooms; for industrial applications, calculate the required moisture removal in pints or liters per day and confirm the range of industrial dehumidifiers that match that capacity. Consider footprint, ducting needs, and whether a custom dehumidification system is needed for multiple rooms or complex spaces.

Industrial or commercial: What are the most common applications for a large industrial dehumidifier in an industry?

Industrial applications include warehouses, manufacturing, cold storage, greenhouses, indoor pools, paint booths, and water damage restoration. Dehumidifiers can be used in any setting where controlling humidity is critical to product quality, worker safety, or building integrity. Facility managers choose units based on dehumidification needs, reliability, and ability to handle excess moisture and condensate over long operating cycles.

Commercial dehumidifier: How do dehumidifiers help with indoor pools and pool areas?

Indoor pools generate high humidity levels that can damage structures and create uncomfortable conditions. Commercial dehumidifiers for pool areas are designed to remove large amounts of moisture, control RH, and manage condensate. They protect finishes and steel cabinets from corrosion, reduce energy costs by improving HVAC efficiency, and extend the lifespan of building components when matched to pool size, cubic feet of air, and ceiling height.

Desiccant dehumidifiers: What is the maintenance that increases the reliability and lifespan of an industrial dehumidifier?

Regular maintenance significantly enhances reliability and lifespan: clean or replace filters, inspect condensate drains and pumps, check refrigerant levels (for refrigerant units), service desiccant wheels or rotors as needed, and verify controls and sensors for accurate RH readings. Proper installation with adequate airflow and periodic professional service helps keep high-performance units operational in demanding environments.

Water damage restoration: Can dehumidifiers be used in cold, wet environments, and how do they manage condensate?

Dehumidifiers can be used in cold environments, but desiccant models are preferable when temperatures drop below the efficient range of refrigerant units. Condensate management is critical: many industrial dehumidifiers include internal condensate pumps, large drain connections, or options for remote condensate removal. Ensure the unit’s condensate capacity and materials are suited for your application to avoid freezing or overflow issues.

Room dehumidifiers: How do I choose between a standard unit and a custom dehumidification system for my facility?

If you have unique dehumidification needs—multiple zones, very large cubic feet volumes, critical RH tolerances, or specialized industrial processes—a custom dehumidification system may be warranted. Standard room dehumidifiers or commercial dehumidifiers work well for single rooms or straightforward applications. Consult with manufacturers or HVAC professionals to evaluate square footage, ceiling height, footprint constraints, and long-term reliability to