Dehumidifiers are reliable home complements in maintaining a comfortable and healthy atmosphere, especially in high-humidity locations. The unexpected problem arises when the dehumidifier suddenly freezes up. When you have seen your dehumidifier getting frosted or iced, you might wonder what went wrong and possibly how to fix it. This comprehensive guide explores the common reasons behind dehumidifier ice buildup, how it affects your device’s performance, and what you can actually do to prevent or fix it.

How Dehumidifiers Work

The Process of Moisture Extraction

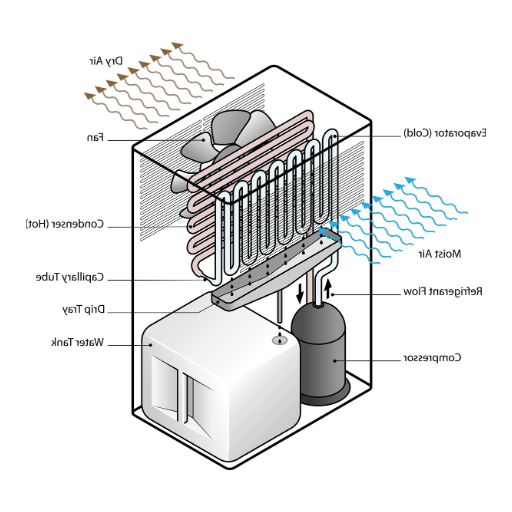

Dehumidifiers function by removing excessive moisture from the air through a simple yet effective process:

- Air Intake: Humid air is drawn inside by the fan

- Cooling Process: Air moves over cooling coils, causing them to cool down

- Condensation: Moisture in the cooled air condenses into water droplets

- Collection: Water is collected in a reservoir or discarded through drainage

- Air Warming: Drier air passes over the heating element to reach a comfortable temperature

- Release: Warm, dry air is released back into the room

Key Success Factors: Various factors, like room size, humidity levels, and the capacity of the dehumidifier, determine how well this process works. Regular maintenance is essential for greater efficiency throughout the process.

The Role of Refrigerant Coils

Refrigerant coils ensure the heat exchange mechanisms required for moisture removal through dehumidifiers. These coils, typically made from copper and aluminum, provide several critical functions:

| Function | Description | Impact on Performance |

|---|---|---|

| Condensation Process | Cool coil surfaces below the dewpoint temperature to turn water vapor into liquid droplets | Enables primary moisture removal function |

| Material & Durability | High-grade materials like copper or aluminum offer superior thermal conductivity | Ensures long-term reliability and corrosion resistance |

| Energy Conservation | Efficient heat exchange enhances overall performance | Reduces energy consumption and operating costs |

| Frost Prevention | Maintaining proper temperature ranges prevents frost formation | Avoids interruption of the dehumidification process |

| Maintenance Requirements | Regular cleaning removes dust and debris buildup | Maximizes efficiency and extends unit lifespan |

Importance of Airflow in Dehumidification

Airflow is crucial for the dehumidification process because it circulates damp air through the dehumidifier, helping remove excess humidity from the atmosphere. Good airflow guarantees that air interacts properly with the refrigerant coils, where moisture absorption takes place.

Warning: Constrained or insufficient airflow may lead to uneven humidity distribution and force the dehumidifier to work harder, increasing energy consumption and stressing internal components, which can reduce working life.

Tips for Optimal Airflow:

- Place the unit in an open spot, free from obstruction

- Maintain clean air filters by cleaning or replacing them when necessary

- Eliminate dust or debris buildup around the system

- Ensure proper treatment and placement for faster moisture extraction

Signs of Ice Buildup on Coils

Visual Indicators of Icing

One obvious indication of ice forming on dehumidifier coils is the formation of a thin layer of frost or ice on the evaporator coils. When humid air encounters cold coil surfaces, moisture condenses before freezing. Regular visual checks help detect this problem early.

Primary Visual Signs:

- Thin layer of frost or ice on evaporator coils

- Increasing thickness of ice blockage over time

- Visible ice aggregation on coil surfaces

- Reduced airflow through the system

Performance Issues: Unit Freezing

Unit freezing commonly occurs when ambient temperatures reach levels below the dehumidifier’s operating range, typically around 65°F (18°C) for standard models. Ice formation results from normal condensation combined with very cold coils.

Solutions for Unit Freezing:

- Ensure operation within recommended temperature ranges

- Consider low-temperature or desiccant dehumidifiers for colder locations

- Clean air filters regularly to prevent blocked airflow

- Place the unit in an area with decent air circulation

- Allow complete thawing before restarting frozen units

Unusual Noises from the Fan Motor

Strange noises from the fan motor might indicate issues requiring immediate intervention. These sounds can include:

- Humming: Often indicates motor bearing wear

- Vibrating: May suggest loose mounting or misalignment

- Grinding: Typically indicates internal component wear

- Squealing: Usually suggests belt or bearing problems

Maintenance Tips to Prevent Icing

Routine Cleaning of Filters and Coils

Dirty filters and coils hamper system performance and shorten useful life. Buildup of dirt and debris limits airflow and diminishes heat exchange capability, leading to increased energy consumption.

Cleaning Process:

- Turn off the system completely to avoid electrical hazards

- Remove and wash filters with lukewarm water and mild detergent

- Dry filters thoroughly before reinstalling to prevent mold formation

- Clean coils with a soft brush or a vacuum cleaner with a brush attachment

- Apply a professional coil cleaning solution for thorough cleaning

Regular Inspections of the Unit

Regular inspections retain long-term efficiency and prevent unexpected breakdowns. During inspections, check these components:

| Component | What to Check | Warning Signs |

|---|---|---|

| Coils | Ice buildup, dirt accumulation | Frost formation, reduced performance |

| Filters | Cleanliness, proper fit | Visible dirt, restricted airflow |

| Fans | Operation, unusual sounds | Grinding, squealing, vibration |

| Refrigerant Levels | Adequate levels, leaks | Poor cooling, visible leaks |

| Overall Performance | Energy efficiency, humidity control | High energy bills, poor humidity control |

Proper Placement of the Dehumidifier

Correct placement is imperative for optimal functioning and efficiency. Consider these placement guidelines:

Placement Best Practices:

- Maintain 6-12 inches of clearance around the unit

- Avoid placement against walls or near furniture

- Choose a central position or area with free air circulation

- Target high-moisture areas like basements, bathrooms, and laundry rooms

- Keep doors and windows closed in the treated area

- Place on a flat, stable surface (not carpet)

- Position near the drain or sink if using direct drainage

Best Practices for Optimal Use

Using the Dehumidifier in Recommended Conditions

Operating within recommended environmental conditions is paramount for efficient dehumidifier performance:

- Temperature Range: 65°F (18°C) to 86°F (30°C)

- Humidity Range: Maintain 30-50% relative humidity

- Monitoring: Use the built-in hygrometer for current humidity readings

- Maintenance: Keep filters clean and empty the water collection tank regularly

Understanding the Role of Thermostat Settings

Thermostat settings significantly determine comfort and energy efficiency. Proper programming maximizes comfort while minimizing energy consumption:

Energy-Saving Guidelines:

- Winter: 68°F when awake, reduce when sleeping or away

- Summer: 78°F for comfort, raise when away

- Smart Features: Utilize humidity sensors for automatic adjustments

Monitoring Humidity Levels Effectively

Tracking indoor humidity levels is important for a balanced and healthy living environment. The perfect humidity levels are normally between 30% and 50%.

Monitoring Tools:

- Smart thermostats with humidity sensors

- Standalone hygrometers for backup monitoring

- Real-time data systems with automatic adjustments

When to Seek Professional Help

Signs of Wear and Tear to Look For

Identifying signs of wear and tear is crucial for maintaining HVAC and dehumidifier functionality:

| Warning Sign | Possible Cause | Action Required |

|---|---|---|

| Reduced Performance | Component wear, blockages | Professional inspection |

| Unusual Noises | Mechanical system failure | Immediate attention |

| Increased Energy Bills | System inefficiency | Energy audit and repair |

| Excessive Cycling | Thermostat or internal problems | Professional diagnosis |

| Visible Damage/Leaks | Component failure | Immediate professional service |

| Unusual Odors | Electrical faults, contaminants | Safety inspection required |

Determining If Replacement Is Necessary

Several factors determine when HVAC system replacement becomes necessary:

Replacement Indicators:

- Age: Systems 10-15 years old become less energy efficient

- Frequent Repairs: Expensive, frequent breakdowns indicate the end of useful life

- Energy Efficiency: Poor SEER ratings compared to modern units

- Refrigerant Issues: Systems using phased-out refrigerants like R-22

- Performance Problems: Inconsistent temperature control despite maintenance

Frequently Asked Questions (FAQ)

References

- Improving dehumidification energy efficiency at a large facility in Florida – Discusses energy use and management in dehumidification systems, including icing problems

- Icing Mitigation Via High-Pressure Membrane Dehumidification in an Aircraft Thermal Management – Studies icing in dehumidification systems under specific conditions

- Measure Guideline: Supplemental Dehumidification in Warm-Humid Climates – Addresses dehumidification, airflow, and temperature control issues related to icing

- Improved Desiccant Evaporative Air-Conditioning (DEVap): Evaluation of an Innovative Ultra-Efficient A/C Concept – Reviews desiccant dehumidification technologies and operational challenges, including icing hazards