Solutions Centre

Our Solutions

Food Production

Causes of High Humidity in Food Production

High humidity in food production environments often arises from activities such as cooking, washing, and steaming, which release large amounts of moisture into the air. Inadequate ventilation or poor air exchange compounds the issue, trapping humidity and creating an unstable environment.

External factors also play a role. In regions with naturally high humidity or during wet seasons, moisture can infiltrate the facility through poorly sealed doors, windows, or walls. This combination of internal and external factors leads to problems like mold growth, bacterial contamination, and compromised product quality.

Effective Solutions for Moisture Control

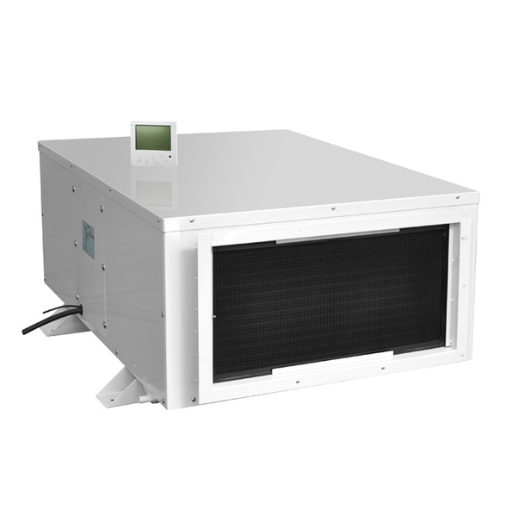

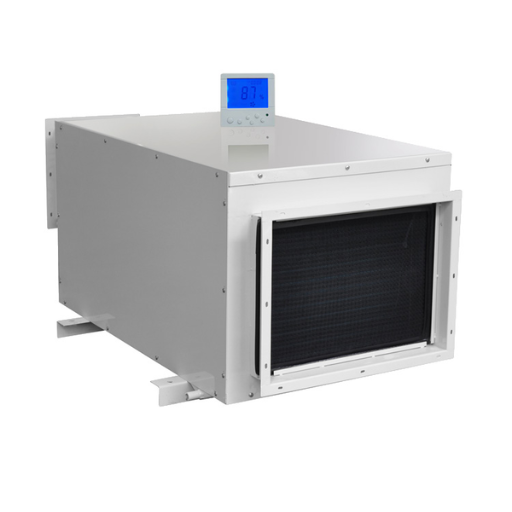

To address humidity challenges in food production, implementing targeted solutions is essential. Industrial-grade dehumidifiers, such as desiccant models, are particularly effective as they maintain low humidity levels even in low-temperature environments like cold storage areas.

For facilities with ongoing moisture production, dehumidifiers with built-in pumps ensure continuous drainage, enabling uninterrupted operation. Complementing these systems with enhanced ventilation improves airflow, preventing moisture from settling. Key measures include:

- Installing industrial dehumidifiers suited to the facility’s size and needs.

- Sealing entry points like windows and doors to prevent external moisture infiltration.

- Using sensors to monitor humidity levels in real time for proactive adjustments.

Maintaining Hygienic and Efficient Operations

Uncontrolled humidity in food production facilities poses significant risks, including compromised hygiene, product spoilage, and equipment damage. By implementing advanced dehumidification systems tailored to the unique needs of food production, facilities can maintain consistent air quality and meet stringent industry standards. This ensures product integrity, reduces waste, and supports efficient and hygienic operations.